In the fast-paced and rapidly evolving world of semiconductor technology, innovation is at the heart of progress. One significant innovation that's making waves in the industry is the integration of PEEK (Polyether Ether Ketone) material. With its exceptional properties and versatile applications, PEEK is ushering in a new era of precision, reliability, and efficiency in semiconductor manufacturing and processes.

PEEK's role in the semiconductor industry is multifaceted, addressing challenges ranging from material durability to high-precision manufacturing. As a high-performance thermoplastic, PEEK possesses remarkable properties such as high-temperature resistance, mechanical strength, and chemical stability. These attributes make PEEK an ideal candidate for various semiconductor applications, where precision and reliability are paramount.

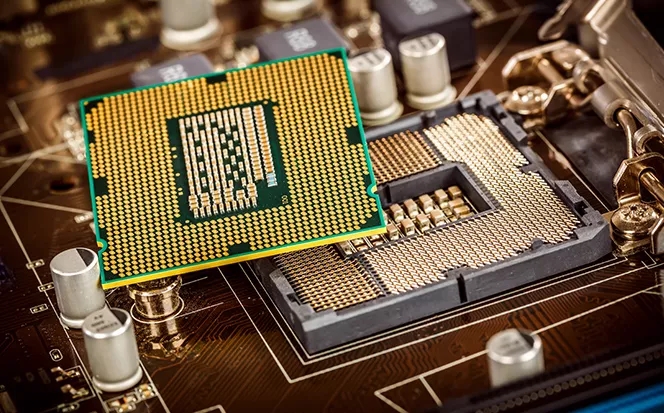

One of the areas where PEEK has made a significant impact is in the manufacturing of semiconductor components. PEEK's exceptional thermal stability allows it to withstand the demanding conditions of semiconductor fabrication processes, ensuring consistent performance even in high-temperature environments. This is crucial for maintaining the accuracy and reliability of delicate semiconductor components.

PEEK's chemical resistance makes it well-suited for processes involving harsh chemicals and reactive gases, which are often used in semiconductor manufacturing. Its ability to maintain its properties even in corrosive environments contributes to the longevity of equipment and components, reducing maintenance costs and downtime.

In addition to its use in manufacturing equipment, PEEK is also employed in the production of specialized components within semiconductor devices. Its low-friction surface and high electrical insulation properties are particularly valuable in applications that require smooth movement and minimal signal interference.

Furthermore, PEEK's compatibility with advanced manufacturing techniques, such as 3D printing, opens up new possibilities for designing intricate and customized semiconductor components. This adaptability allows for the creation of complex geometries and optimized structures, leading to improved performance and efficiency.

As the semiconductor industry continues to push the boundaries of technology, PEEK's contributions are driving advancements in precision, reliability, and efficiency. Its presence is not only enhancing the performance of semiconductor components but also shaping the way manufacturing processes are carried out.

In conclusion, PEEK's integration into the semiconductor industry is a testament to its versatility and potential. Its unique combination of properties addresses the industry's most pressing challenges and is unlocking new opportunities for innovation. As the semiconductor industry evolves, PEEK's role as a high-performance material is set to play a crucial part in shaping its future, driving progress and pushing the boundaries of what's achievable in precision technology.