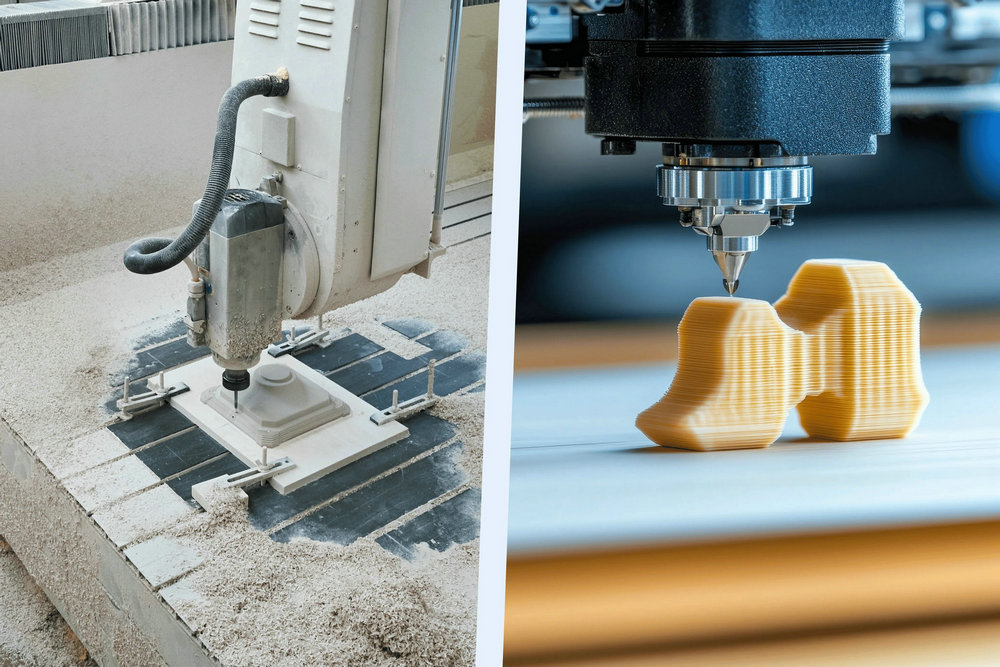

CNC machining offers superior precision, achieving tolerances as tight as ±0.005 mm. This results in smooth surfaces with minimal post-processing.

In contrast, PEEK 3D printing usually results in thicker layer lines (0.1 to 0.5 mm), requiring additional finishing for surface quality and accuracy.

CNC-machined PEEK parts are isotropic with consistent mechanical properties.

3D printed PEEK parts may show anisotropy due to the layer-by-layer method, though newer technologies are improving strength and consistency.

PEEK 3D printing allows for complex geometries, internal channels, and lightweight lattice structures, which are hard or impossible to achieve with CNC machining.

CNC is ideal for simple, high-precision parts but struggles with internal or undercut features.

3D printing has low setup costs, making it ideal for low-volume production or rapid prototyping.

CNC has higher initial setup costs, but becomes more cost-efficient for medium to large production runs.

In CNC machining, costs rise with increased complexity due to longer machining times and tooling requirements.

In 3D printing, cost is relatively stable regardless of part complexity.

Both methods are costly due to the high price of PEEK.

3D printing often leads to more material waste (support structures), while CNC may waste less depending on part geometry.

PEEK 3D printing is faster for prototypes or small, intricate parts, often allowing overnight production.

CNC is typically faster for large batches or simple designs but involves longer setup times.

| Aspect | PEEK 3D Printing | CNC Machining (PEEK) |

| Precision | Moderate (±0.1–0.5 mm, layer lines visible) | High (±0.005 mm, smooth finish) |

| Material Integrity | Anisotropic (layer-by-layer) | Isotropic (strong and uniform) |

| Design Complexity | Excellent for complex/internal features | Limited by tool access |

| Setup Cost | Low | High |

| Cost per Part | Lower for low volumes | Lower for high volumes |

| Production Speed | Fast for small runs | Fast for large batches |

| Surface Finish | Requires post-processing | Typically smooth, minimal finishing |

PEEK 3D printing provides excellent flexibility, quick prototyping, and lower costs for low-volume, complex parts, albeit with moderate precision and strength variations.

CNC machining excels in precision, consistency, and scalability, making it a better choice for high-volume production and critical mechanical applications.

Your choice should depend on design complexity, production volume, performance requirements, and budget.