A labyrinth seal consists of a series of annular sealing teeth arranged around a rotating shaft. The gaps and expansion chambers formed between the teeth create a tortuous path, inducing a throttling effect that prevents leakage as the sealed medium passes through the maze-like structure.

Because there is a clearance between the rotor and the casing in a labyrinth seal—with no solid contact—no lubrication is required. This design accommodates thermal expansion, making it suitable for high temperature, high pressure, and high-speed applications. It is widely used in steam turbines, gas turbines, compressors, blowers, and as a pre-sealing mechanism for other dynamic seals.

The “labyrinth effect” is the phenomenon where fluid flow is impeded and reduced through a labyrinth, resulting in sealing action. The mechanisms are:

Viscosity in the fluid generates friction during flow, which reduces velocity and leakage. Longer flow paths with sharper turns and pointed tooth shapes increase resistance, lowering leakage.

As fluid passes through narrow gaps, inertia causes the flow jet to contract. The contraction coefficient (Cc) and velocity coefficient (Cd) affect flow rate. Pointed teeth have a lower flow coefficient (~0.7), while rounded teeth have one closer to 1.0.

Gas accelerates and compresses at the gap inlet, reaching high velocity. Upon entering the expansion chamber, it suddenly expands and creates turbulence. Most of the kinetic energy converts to heat, reducing pressure and velocity before the next gap.

Not all kinetic energy converts to heat, especially in compact chambers. Some gas bypasses the expansion zone at high speed—this is called the "bypass effect."

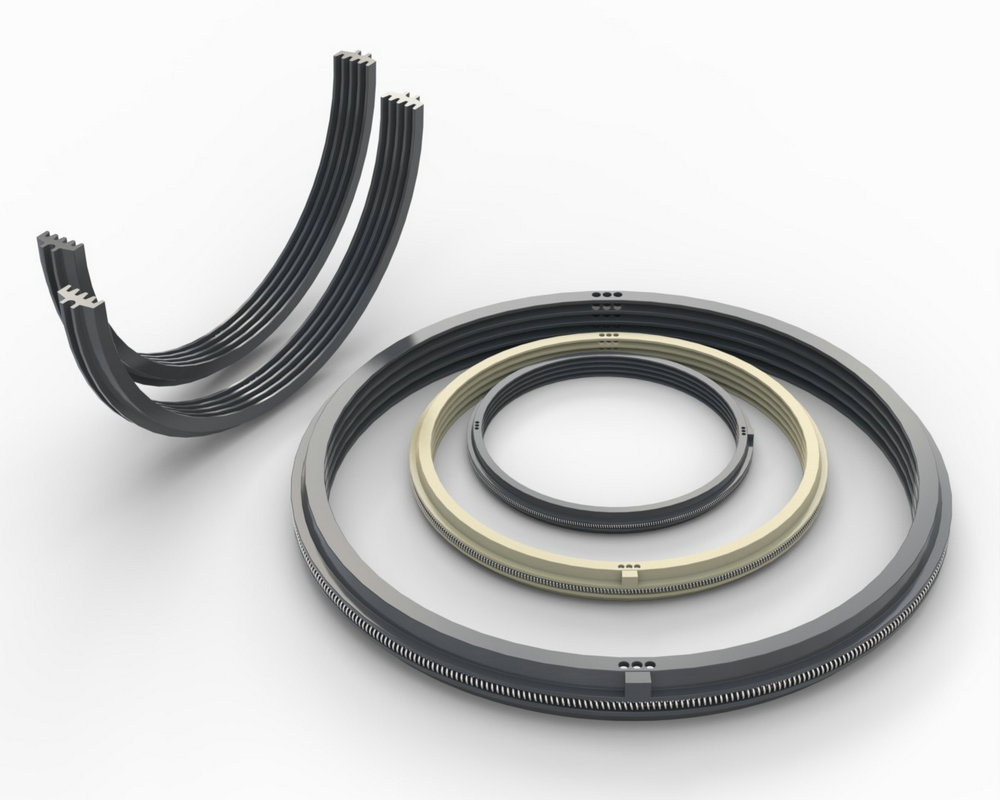

Labyrinth seals come in two main forms based on the structure of the sealing teeth:

Sealing Strips: Compact and can bend to reduce friction if they come into contact with the housing. Easy to replace.

Sealing Rings: Made of 6–8 segments pressed by springs against the housing. More complex and larger, requiring full replacement when worn.

Assumptions for leakage calculation:

Ideal gas behavior; no Joule–Thomson effect.

Continuous series of gaps with large expansion chambers.

Adiabatic expansion with flow coefficient α.

Full kinetic-to-thermal energy conversion; no bypass flow.

These are formed by machining grooves or teeth into the shaft, which is easier than machining the bore. While cost-effective and widely used, through-type seals exhibit more bypass flow and higher leakage than ideal labyrinths.

Tooth Count and Pitch: More teeth = less leakage; larger pitch = reduced bypass flow.

Expansion Chamber Depth: Shallow chambers lead to unstable vortices that quickly dissipate energy, reducing leakage.

Auxiliary Chambers: Strategically placed side grooves in smooth-bore labyrinths significantly reduce leakage.

Used in turbines and other rotating machinery, the radial clearance depends on:

Bearing clearance

Manufacturing tolerances

Assembly errors

Thermal deformation

Rotor deflection

Critical speed vibrations

Thermal expansion is a critical consideration, especially during startup/shutdown. Finite element analysis is often used to simulate this behavior and optimize clearances.

Maximize kinetic-to-thermal energy conversion; prevent residual velocity from entering the next gap. Use high-low tooth configurations or maintain 5–9 mm spacing.

Teeth should be thin and sharp; tip thickness <0.5 mm to prevent damage during occasional contact.

For flammable, explosive, or toxic gases, use purge-type labyrinths with inert gas or vacuum to avoid contamination.

PEEK (Polyether Ether Ketone) is a high-performance polymer ideal for labyrinth seals due to:

High temperature resistance (up to 260°C)

Excellent chemical resistance

No lubrication required

Low wear and friction

Lightweight and corrosion-resistant

Dimensional stability and strength under load

Its non-metallic nature prevents sparking and is especially beneficial in explosive or flammable gas sealing environments, making PEEK Labyrinth Seals a preferred solution for extreme applications in aerospace, chemical, and energy sectors.