PEEK MATERIAL PERFORMANCE

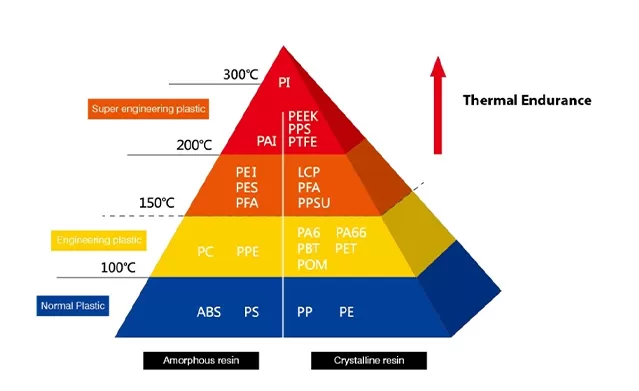

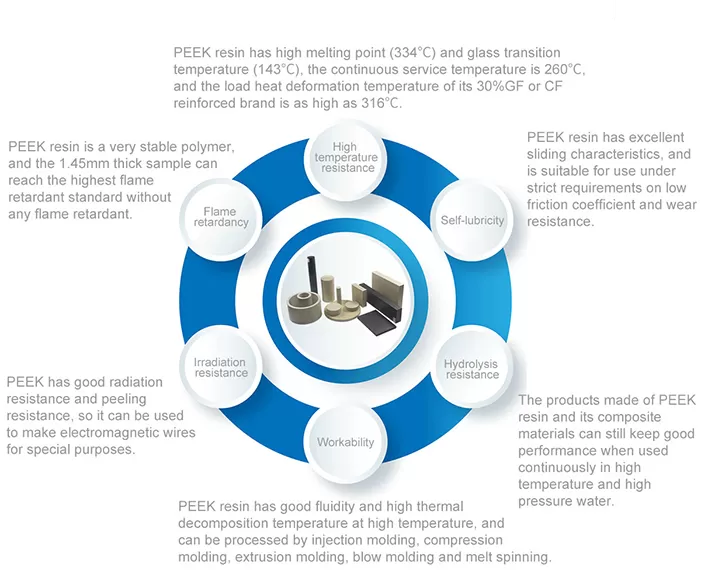

Polyetheretherketone (PEEK) is a high-performance, engineering thermoplastic characterized by an unusual combination of properties. These properties range from high temperature performance to mechanical strength and excellent chemical resistance.

PEEK MATERIAL PROPERTIES

MATERIAL GRADE

ARKPEEK-1000: 100%PEEK 01

Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types.

ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK 02

Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values.

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK 03

Glass filled PEEK exhibits increased mechanical strength and high rigidity. improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite + 70% PEEK 04

High performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical strength and high dimensional stability. The long term service temperature range is from -70°C to 260°C and has a short term maximum service temperature of 310°C.

PEEKCHINA MATERIAL PROPERTIES

| Mechanical Behavior | ||||||

| Item | Test Standard or Instrument | Unit | ARKPEEK-1000 | ARKPEEK-GF30 | ARKPEEK-CF30 | ARKPEEK-MOD |

| 100%PEEK | PEEK+30%Glass Fiber | PEEK+30%Carbon Fiber | PEEK+10%Carbon Fiber+10%Graphite+10%PTFE | |||

| Tensile strength(23℃) | ISO527 | MPa | 100 | 155 | 220 | 134 |

| Bending strength(23℃) | ISO 178 | MPa | 163 | 212 | 298 | 186 |

| Compressive strength(23℃) | ISO 604 | MPa | 118 | 215 | 240 | 150 |

| Lzod impact strength( no gap) | ISO 180/IU | kJ/m² | No Crack | 51 | 46 | 32 |

| Thermal Performance | ||||||

| Item | Test Standard or Instrument | Unit | ARKPEEK-1000 | ARKPEEK-GF30 | ARKPEEK-CF30 | ARKPEEK-MOD |

| 100%PEEK | PEEK+30%Glass Fiber | PEEK+30%Carbon Fiber | PEEK+10%Carbon Fiber+10%Graphite+10%PTFE | |||

| Melting point | DSC 11357 | ℃ | 343 | 343 | 343 | 343 |

| Distortion temperature | ISO 75-1/2 | ℃ | 163 | 315 | 315 | 293 |

| Continuous using temperature | UL 74685 | ℃ | 260 | 260 | 260 | 260 |

Coefficient of thermal expansion | ASTM D696 | 10 -5℃ | 4.7 | 2.2 | 1.5 | 2.2 |

| Flammable level | UL 94 | V-0@mm | 1.5 | 1.5 | 1.5 | 0.75 |

| Electrical Performance | ||||||

| Item | Test Standard or Instrument | Unit | ARKPEEK-1000 | ARKPEEK-GF30 | ARKPEEK-CF30 | ARKPEEK-MOD |

| 100%PEEK | PEEK+30%Glass Fiber | PEEK+30%Carbon Fiber | PEEK+10%Carbon Fiber+10%Graphite+10%PTFE | |||

| Dielectric strength | IEC 60243-1 | kV/mm | 18 | 19 | ||

| Dielectric constant | IEC60250 | - | 3.2 | 3.3 | ||

| Surface resistivity | Ω | 10 15 | 10 15 | 3*10 6 | 5*10 6 | |

| Other Performance | ||||||

| Item | Test Standard or Instrument | Unit | ARKPEEK-1000 | ARKPEEK-GF30 | ARKPEEK-CF30 | ARKPEEK-MOD |

| 100%PEEK | PEEK+30%Glass Fiber | PEEK+30%Carbon Fiber | PEEK+10%Carbon Fiber+10%Graphite+10%PTFE | |||

| Density | ISO 1183 | g/cm3 | 1.3±0.01 | 1.5±0.01 | 1.4±0.01 | 1.43±0.01 |

| Rockwell hardness | ISO 2039 | HRR | 118 | 119 | 121 | 108 |

| Friction coefficient | μ | 0.30-0.38 | 0.38-0.46 | 0.28 | 0.18 | |

| Water Abs. (25℃.24Hrs) | ISO 62 | % | 0.5 | 0.11 | 0.06 | 0.06 |

| Mould shrinking percentage | 3mm,170℃, Flow direction | % | 1.2 | 0.4 | 0.1 | 0.3 |

| Perpendicular to flow direction | % | 1.5 | 0.8 | 0.5 | 0.5 | |