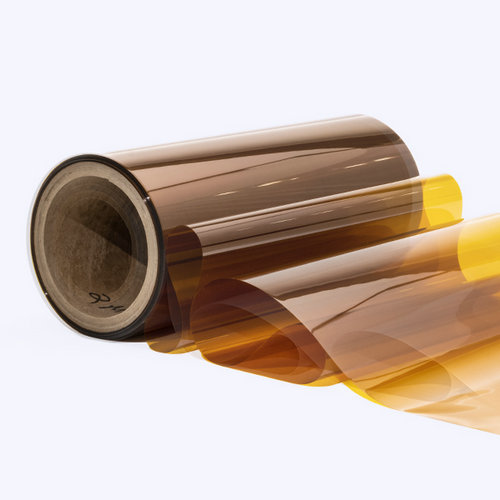

PI Polyimide Film is a high-performance engineering plastic film known for its exceptional thermal stability, electrical insulation, and chemical resistance. With temperature tolerance from -269°C to +400°C, excellent dielectric strength, and flame retardant properties, it is widely used in aerospace, electronics, flexible circuits, and industrial applications requiring durability and precision.

PI Polyimide Film: Exceptional Performance for Extreme Conditions

PI Polyimide Film is engineered for high-performance applications where reliability and durability are critical. This film is known for its superior heat resistance, maintaining its structural integrity even under continuous exposure to temperatures ranging from -269°C to +400°C. Its short-term thermal stability can withstand temperatures as high as 500°C, making it an ideal choice for industries with demanding temperature fluctuations.

Key Properties & Advantages:

Extreme Thermal Stability: PI Polyimide Film offers remarkable thermal resistance, with a continuous use temperature range of -269°C to +400°C and short-term exposure up to 500°C.

Electrical Insulation: The film provides outstanding dielectric strength (up to 300 kV/mm) and stable dielectric properties (ε = 3.0–3.5), making it an excellent material for electrical insulation in circuits and high-voltage applications.

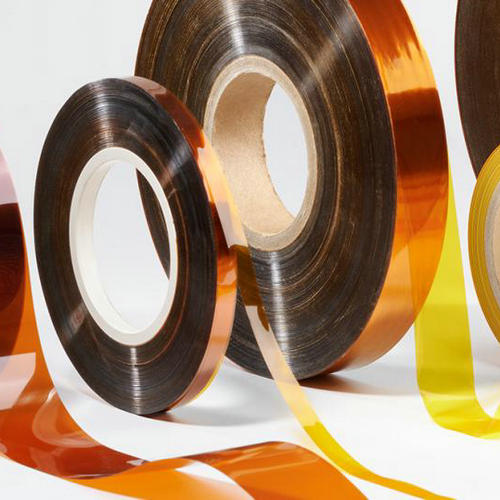

Mechanical Strength & Flexibility: With high tensile strength and low creep, the film exhibits excellent mechanical properties. It can be used in applications requiring both flexibility and strength, such as flexible printed circuits (FPCs) and insulation in cables.

Chemical & Environmental Resistance: Resistant to solvents, fuels, oils, acids, and bases, PI Polyimide Film is designed to perform in harsh chemical environments. It is also UV and radiation resistant, ensuring long-term performance even in exposure to gamma and X-rays.

Low Outgassing: With minimal outgassing (TML <1%, CVCM <0.1%), it is NASA-approved for space applications and cleanroom environments (ISO Class 1–5).

Dimensional Stability: With near-zero thermal expansion (CTE ≈ 20–50 ppm/K), PI Polyimide Film maintains precise dimensional stability even in extreme conditions, making it ideal for aerospace components and electronics.

Applications:

Aerospace & Defense: Used in spacecraft insulation, satellite components, radomes, and thermal barriers.

Electronics: PI Polyimide Film is essential in the production of flexible printed circuits (FPCs), high-performance capacitors, and battery insulation.

Automotive & Energy: Applications include thermal shielding, fuel cell components, and battery separator films.

Medical Devices: The film is used in sterilizable surgical equipment, implantable sensors, and medical tubing.

Industrial & Manufacturing: Flexible heaters, 3D printer parts, vacuum sealing, and chemical processing systems rely on the film’s high resistance and flexibility.

Specifications & Parameters:

Thickness Range: Available in various thicknesses from 12 µm to 250 µm

Tensile Strength: ≥100 MPa

Dielectric Strength: Up to 300 kV/mm

CTE (Coefficient of Thermal Expansion): Approx. 20–50 ppm/K

UV Resistance: Excellent protection against prolonged exposure

Thermal Range: -269°C to +400°C continuous use, up to 500°C short-term exposure

Outgassing Properties: TML <1%, CVCM <0.1% (suitable for space and cleanroom use)

Why Choose PI Polyimide Film?

Customizable Options: Available in various thicknesses, widths, and roll lengths to meet specific application needs.

High-Quality Manufacturing: Produced in certified ISO Class 5 cleanrooms to ensure zero contamination.

Versatile Applications: Ideal for high-performance electronics, aerospace, automotive, and medical industries.

Reliable Supplier: We provide full traceability from raw material to finished product, ensuring quality and reliability.