PI Polyimide Fiber is a high-performance polymer fiber known for its exceptional toughness, high and low temperature resistance, flame retardancy, and radiation resistance. It features low density, low dielectric constant, low water absorption, and excellent corrosion and ablation resistance. This fiber is ideal for special rope and cable sheathing, nuclear industry applications, and high-temperature protective materials.

PI Polyimide Fiber – Engineered Performance in the Harshest Environments

PI Polyimide Fiber is a high-performance synthetic fiber known for its outstanding combination of mechanical strength, heat resistance, flame retardancy, and environmental stability. Engineered from aromatic polyimide polymers, this fiber performs reliably under extreme temperature conditions, ranging from -200°C to +300°C, with excellent retention of properties during long-term thermal exposure and short-term spikes up to 500°C.

Its high toughness and low density make it ideal for aerospace and energy sector applications where lightweight reinforcement is critical. Unlike conventional heat-resistant fibers, PI Fiber delivers superior dimensional stability, radiation resistance, chemical durability, and low moisture absorption, ensuring consistent performance in high-radiation, corrosive, or vacuum environments.

Key Features and Advantages

High Strength and Toughness: Strong tensile performance with excellent resistance to mechanical stress and fatigue

Wide Temperature Range: Stable performance from -200°C to +300°C, withstanding instantaneous peaks up to 500°C

Flame Retardant and Fireproof: Naturally self-extinguishing and compliant with UL94 V-0 standards

Thermal Insulation and Ablation Resistance: Ideal for protective heat shields, thermal linings, and aerospace-grade insulation

Radiation Resistance: Withstands gamma rays, electron beams, and ultraviolet radiation with minimal degradation

Low Dielectric Constant: Suitable for applications requiring electromagnetic transparency or electrical insulation

Corrosion and Chemical Resistance: Resistant to acids, bases, fuels, oils, and most organic solvents

Low Moisture Absorption: <1% water uptake, ensuring dimensional stability and reliable performance in humid environments

Lightweight: Density: ~1.4 g/cm³, making it much lighter than metallic or ceramic insulation alternatives

Applications

Aerospace and Aviation: Fireproof textile layers, ablation shields, lightweight reinforcement yarns

Nuclear Industry: Protective sheathing, thermal insulation, radiation shielding fabrics

High-Temperature Cable Wrapping: Braided sleeving and jackets for extreme heat environments

Thermal and Fire Barriers: Linings for furnaces, combustion chambers, and exhaust insulation

Military and Defense: Heat-protective suits, high-temperature rope, missile and engine insulation

Specialty Composites: Reinforcement fiber in heat-resistant laminates and polymer composites

Advanced Filtration: Fiber media for hot gas filtration in chemical processing and waste incineration

Specifications & Parameters

Material Type: Polyimide (aromatic structure)

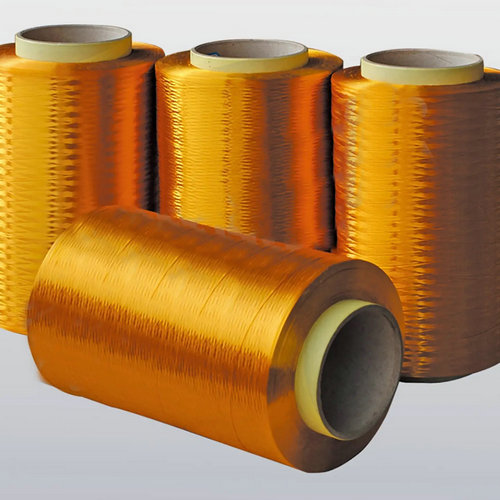

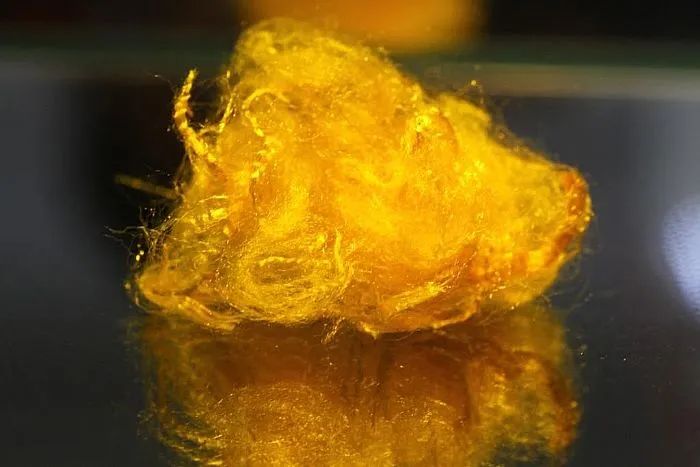

Fiber Form: Continuous filament, staple fiber, yarn, or tow

Density: Approx. 1.4 g/cm³

Tensile Strength: ≥500 MPa

Modulus: ≥10 GPa

Thermal Stability: Continuous at 300°C, short-term up to 500°C

Dielectric Constant: ~3.3 (stable across temperature/frequency)

Moisture Absorption: <1%

Radiation Resistance: Excellent under gamma, UV, and high-energy radiation

Standard Packaging: Bobbins, rolls, or customized formats per request

Color: Typically golden-yellow to amber (custom coloration available)

Why Choose Our PI Polyimide Fiber?

Custom Formats Available: Yarn, tow, chopped fiber, woven or nonwoven fabric

Tested & Certified: Meets standards for flame retardancy, outgassing, and radiation resistance

Precision Production: Manufactured under tightly controlled conditions for critical-use environments

Application Support: Technical assistance and customization for aerospace, nuclear, and industrial customers

Global Supply Ready: Fast delivery, consistent quality, and flexible order volumes