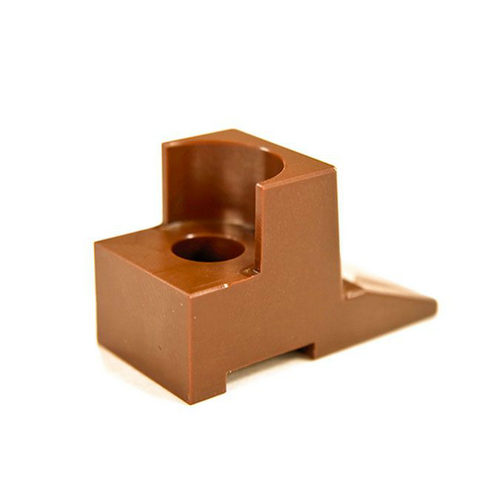

PI Polyimide Components are precision machined parts made from high-performance polyimide polymers known for exceptional thermal stability, chemical resistance, and outstanding wear properties. Ideal for aerospace, electronics, and industrial applications, these components offer excellent electrical insulation, dimensional stability, and flame retardancy.

Product Name: PI Polyimide Components | Parts

Material: ARKPI - High-Performance Thermosetting Polyimide

Temperature Range: -269°C to +400°C (short-term up to 500°C)

Key Properties: Heat resistant, high strength, chemically inert, electrical insulation, radiation resistant

Description:

PI Polyimide Components are precision-engineered parts designed to perform in the harshest environments—where high heat, aggressive chemicals, and mechanical stress destroy most conventional materials. With excellent thermal stability across a wide temperature range from cryogenic conditions up to 400°C continuous use (500°C short-term), these components maintain structural integrity and dimensional stability under extreme thermal cycling.

They exhibit superior chemical resistance to fuels, acids, bases, and organic solvents, making them ideal for demanding applications in the semiconductor, aerospace, medical, and chemical processing industries. Their outstanding mechanical strength (tensile strength ≥100 MPa) and low creep allow them to support long-term structural loads and dynamic motion.

PI Polyimide Components also provide excellent electrical insulation with dielectric strength up to 300 kV/mm and a stable dielectric constant of 3.0–3.5, ensuring reliable performance in high-voltage and high-frequency systems. Resistant to gamma rays, X-rays, and UV, they are well-suited for aerospace and nuclear environments.

These components are vacuum-compatible, with low outgassing (TML <1%, CVCM <0.1%), making them safe for use in ISO Class 1–5 cleanrooms, space-grade hardware, and ultra-sensitive optical systems.

Typical Component Types & Applications:

Bearings & Bushings: High-load rotating systems, low-friction dry environments

Seals & Valve Seats: Chemical pumps, high-temperature sealing systems

Wafer Carriers & Tooling Fixtures: Semiconductor handling and transport

Thermal Sleeves & Electrical Insulators: Jet engines, electronic modules

Sensor Housings & Surgical Instrument Parts: Biocompatible, sterilizable applications

Fuel Cell Plates & Battery Insulation Components: Energy storage and delivery systems

End-Use Industries:

Aerospace & Defense: Missile systems, turbine components, satellite parts

Electronics & Semiconductors: Chip packaging, wafer transfer arms

Medical & Life Sciences: Surgical handles, implantable housings

Energy Sector: Fuel cells, nuclear reactor insulation

Advanced Manufacturing: Cleanroom automation, 3D printer hot zones

Manufacturing Methods:

CNC Machining from solid PI rod or plate

Compression Molding for dense, high-precision parts

Injection Molding for complex shapes (custom tooling available)

Post-processing: Annealing, laser trimming, surface etching, fluorination

Quality Standards & Testing:

Compliant with MIL-P-46179, ASTM D7992

Manufactured in ISO Class 5 cleanroom environments

Thermal Testing: TGA, DSC (ASTM E1131, E793)

Mechanical Testing: ASTM D638, D695

Electrical Testing: IEC 60243

Biocompatibility Testing: USP Class VI, ISO 10993

Why Choose Our PI Polyimide Components:

Fully customizable geometry and formulations (e.g., graphite- or PTFE-filled)

Cleanroom-manufactured with zero contamination and full traceability

Engineered for performance in failure-critical applications

Technical support available for co-design and application engineering