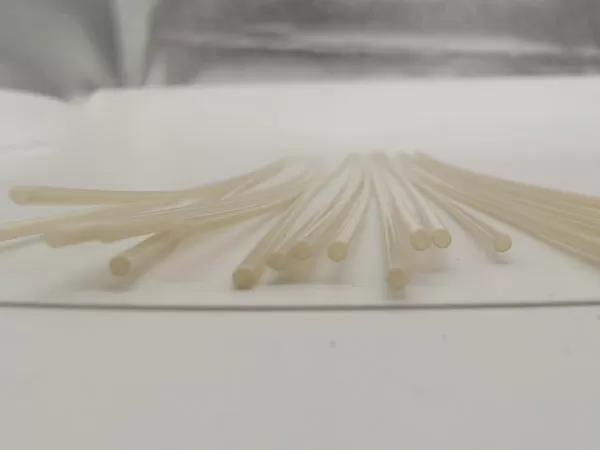

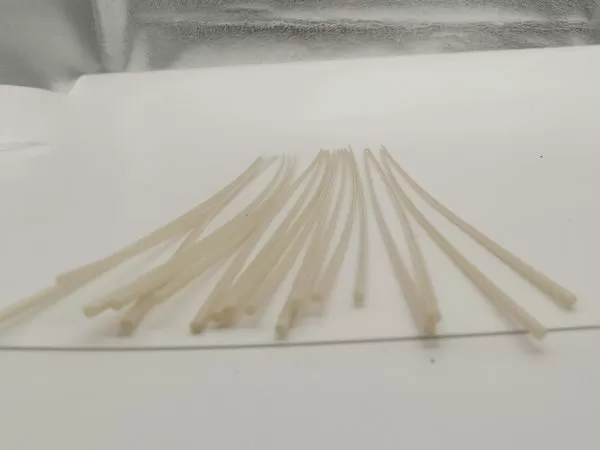

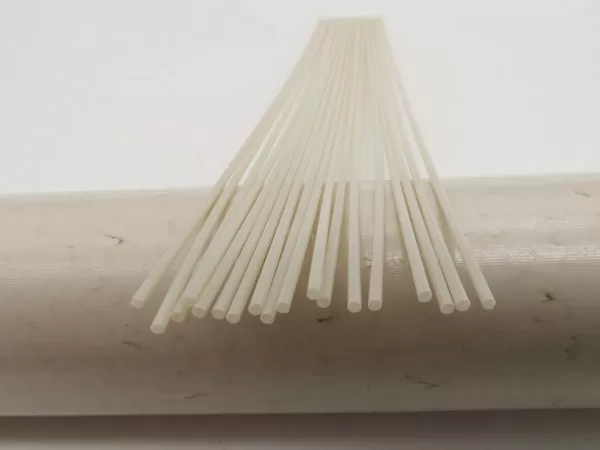

Medical-grade, Biocompatible PEEK Polymer Materials

Our medical-grade PEEK shaft liners are designed to ensure safe and reliable delivery of medical liquids. These PEEK tubing liner are made from durable and corrosion-resistant polyetheretherketone polymer material, and reduce friction and wear during delivery. Invest in the safety and reliability of your medical liquid delivery system with our high-quality PEEK shaft liners.

Key Features of PEEK Liner Tubing:

• Ultra hard material

• Very good chemical resistance

• Stable at temperatures up to 228°C

• Excellent abrasion resistance

• Flame retardant (UL94 V-0)

• Very tight dimensional tolerances

PEEK Tubing:

• In coils, on spools or straight lengths with clean, square cuts

• Translucent or Opaque

• Wall thickness varying along length (Bumped tubing)

• Coloured PEEK tubing

• Multi-Layer PEEK tubing

• Reinforced PEEK tubing (Stainless Steel Wires)

• Shaped tubing

| Properties Information | ||||||

| Property | Reference Standard | Test Method | Unit | Specification | Result | |

| Physical Properties | Glass Transition | ASTM F2026 | ASTM D3418 | °C | 125-165 | 147 |

| Temperature, Tg | ||||||

| Melt Temperature, Tm | ASTM F2026 | ASTM D3418 | °C | 320-360 | 338 | |

| Recrystallization | ASTM F2026 | ASTM D3418 | °C | 260-320 | 289 | |

| Temperature, Tc | ||||||

| Viscosity | ASTM F2026 | ISO 11443 | Pa·s | 400-480 | 437 | |

| Infrared Spectrum | ASTM F2026 | ASTM F1579 | / | See Appendix X1 | See Appendix X2 | |

| Density | ASTM F2026 | ASTM D1505 | kg/m3 | 1280-1320 | 1294 | |

| Chemical Properties | Total Heavy Metals (Ag, As, Bi, Cd, Cu, Hg, Mo, Pb, Sb, and Sn), max | ASTM F2026 | US Pharmacopeia, | ppm | <100 | <10 |

| Test 233 | ||||||

| Mechanical Properties | Tensile Strength at Yield (zero slope), min | ASTM F2026 | ASTM D638, Type IV, 5.08 cm/min | MPa | 90 | 105 |

| Tensile Strength at Break, min | ASTM F2026 | ASTM D638, Type IV, 5.08 cm/min | MPa | 70 | 80 | |

| Elongation at Break, min | ASTM F2026 | ASTM D638, Type IV, 5.08 cm/min | % | 5 | 18 | |

| Flexural Strength, min | ASTM F2026 | ASTM D790 | MPa | 110 | 163 | |

| Flexural Modulus, min | ASTM F2026 | ASTM D790 | GPa | 3 | 4 | |

| Impact Strength, | ASTM F2026 | ISO 180 | kJ/m2 | 4 | 9 | |

| Notched Izod, min | ||||||

| Biological Properties | Genotoxicity | ISO 10993-3 | ISO 10993-3 | / | Negative | Negative |

| Animal Intracutaneous (Intradermal) Reactivity | ISO 10993-10 | ISO 10993-10 | / | ≤1 | 0 | |

| Skin Sensitization | ISO 10993-10 | ISO 10993-10 | / | ≤1 | 0 | |

| Acute Systemic Toxicity | ISO 10993-11 | ISO 10993-11 | / | No Acute Systemic Toxicity | No Acute Systemic Toxicity | |

| Subchronic Systemic Toxicity | ISO 10993-11 | ISO 10993-11 | / | No Subchronic Systemic Toxicity | No Subchronic Systemic Toxicity | |

| local Effects After Implantation | ISO 10993-6 | ISO10993-6 | / | No obvious difference between the test sample and the control sample | No obvious difference between the test sample and the control sample | |

| In Vitro Cytotoxicity | ISO 10993-5 | ISO10993-5 | / | ≤1 | 1 | |

| Evaluation of Haemolytic Properties | ISO 10993-4 | ISO10993-4 | % | <5 | 1 | |

| Material Mediated Pyrogens | ISO 10993-11 | ISO 10993-11 | / | No Pyrogenic Responses | No Pyrogenic Responses | |

| Extractables of The Material | ISO 10993-18 | ISO 10993-18 | μg/g | The contents of Phenyl Sulfone≤300 | The contents of Phenyl Sulfone<0.09 | |