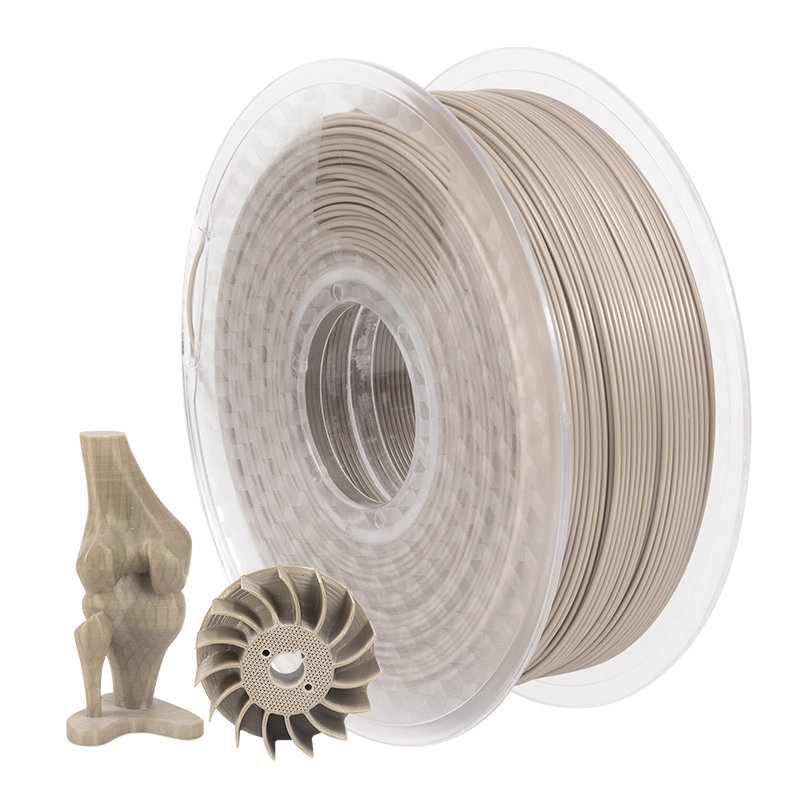

ARK-BioPEEK medical grade PEEK filament is a high-performance, biocompatible material specially formulated for 3D printing implantable medical devices and surgical instruments. It offers excellent chemical resistance, sterilizability, and mechanical strength for reliable, patient-specific solutions.

_______________________________________________________________________________________________________________________________________________________________________

ARK-BioPEEK medical grade PEEK filament is an advanced thermoplastic filament designed for additive manufacturing of implantable medical devices and surgical tools using professional fused filament fabrication (FFF) 3D printers. Produced under stringent cleanroom conditions and quality management systems, this filament meets international medical standards such as ASTM F2026, ISO 10993, and USP Class VI, ensuring biocompatibility and safety for long-term implantation.

The filament exhibits outstanding mechanical properties including high tensile strength, impact resistance, and dimensional stability, enabling the production of durable, precise, and customized implants such as spinal cages, cranial plates, dental prosthetics, and orthopedic devices. Its excellent chemical resistance protects against bodily fluids, acids, and solvents, while compatibility with sterilization methods like gamma radiation, autoclaving, and ethylene oxide ensures clinical readiness.

ARK-BioPEEK filament also offers radiolucency, allowing clear medical imaging without interference, and low outgassing to maintain a contamination-free environment during manufacturing and implantation. The filament’s thermal stability supports continuous use at elevated temperatures up to 260°C, making it suitable for demanding medical applications.

By leveraging ARKPEEK medical grade PEEK filament, healthcare providers and manufacturers can produce patient-specific implants and surgical tools with reduced lead times and costs compared to traditional manufacturing methods, while maintaining the highest standards of quality and safety.

Key Benefits

Certified biocompatibility and implant-grade quality

High mechanical strength and durability

Excellent chemical and sterilization resistance

Radiolucent for superior imaging compatibility

Precision 3D printing for customized medical devices

Manufactured in ISO 13485 certified cleanroom environments

Widely used in orthopedic, dental, craniofacial, and trauma applications, ARK-BioPEEK filament empowers innovation in personalized medicine and advanced surgical solutions.

Choose ARKPEEK medical grade PEEK ARK-BioPEEK filament for reliable, high-performance, and customizable 3D printed medical implants and devices.

_______________________________________________________________________________________________________________________________________________________________________

| Properties Information | ||||||

| Property | Reference Standard | Test Method | Unit | Specification | Result | |

| Physical Properties | Glass Transition | ASTM F2026 | ASTM D3418 | °C | 125-165 | 147 |

| Temperature, Tg | ||||||

| Melt Temperature, Tm | ASTM F2026 | ASTM D3418 | °C | 320-360 | 338 | |

| Recrystallization | ASTM F2026 | ASTM D3418 | °C | 260-320 | 289 | |

| Temperature, Tc | ||||||

| Viscosity | ASTM F2026 | ISO 11443 | Pa·s | 400-480 | 437 | |

| Infrared Spectrum | ASTM F2026 | ASTM F1579 | / | See Appendix X1 | See Appendix X2 | |

| Density | ASTM F2026 | ASTM D1505 | kg/m3 | 1280-1320 | 1294 | |

| Chemical Properties | Total Heavy Metals (Ag, As, Bi, Cd, Cu, Hg, Mo, Pb, Sb, and Sn), max | ASTM F2026 | US Pharmacopeia, | ppm | <100 | <10 |

| Test 233 | ||||||

| Mechanical Properties | Tensile Strength at Yield (zero slope), min | ASTM F2026 | ASTM D638, Type IV, 5.08 cm/min | MPa | 90 | 105 |

| Tensile Strength at Break, min | ASTM F2026 | ASTM D638, Type IV, 5.08 cm/min | MPa | 70 | 80 | |

| Elongation at Break, min | ASTM F2026 | ASTM D638, Type IV, 5.08 cm/min | % | 5 | 18 | |

| Flexural Strength, min | ASTM F2026 | ASTM D790 | MPa | 110 | 163 | |

| Flexural Modulus, min | ASTM F2026 | ASTM D790 | GPa | 3 | 4 | |

| Impact Strength, | ASTM F2026 | ISO 180 | kJ/m2 | 4 | 9 | |

| Notched Izod, min | ||||||

| Biological Properties | Genotoxicity | ISO 10993-3 | ISO 10993-3 | / | Negative | Negative |

| Animal Intracutaneous (Intradermal) Reactivity | ISO 10993-10 | ISO 10993-10 | / | ≤1 | 0 | |

| Skin Sensitization | ISO 10993-10 | ISO 10993-10 | / | ≤1 | 0 | |

| Acute Systemic Toxicity | ISO 10993-11 | ISO 10993-11 | / | No Acute Systemic Toxicity | No Acute Systemic Toxicity | |

| Subchronic Systemic Toxicity | ISO 10993-11 | ISO 10993-11 | / | No Subchronic Systemic Toxicity | No Subchronic Systemic Toxicity | |

| local Effects After Implantation | ISO 10993-6 | ISO10993-6 | / | No obvious difference between the test sample and the control sample | No obvious difference between the test sample and the control sample | |

| In Vitro Cytotoxicity | ISO 10993-5 | ISO10993-5 | / | ≤1 | 1 | |

| Evaluation of Haemolytic Properties | ISO 10993-4 | ISO10993-4 | % | <5 | 1 | |

| Material Mediated Pyrogens | ISO 10993-11 | ISO 10993-11 | / | No Pyrogenic Responses | No Pyrogenic Responses | |

| Extractables of The Material | ISO 10993-18 | ISO 10993-18 | μg/g | The contents of Phenyl Sulfone≤300 | The contents of Phenyl Sulfone<0.09 | |

_______________________________________________________________________________________________________________________________________________________________________