China's new energy vehicle (NEV) sales reached 12.87 million units in 2024, representing a year-on-year growth of 35.5%, and are projected to exceed 17 million units by 2025. Against this backdrop, automotive lightweighting has become a critical pathway to improving energy efficiency, extending driving range, and reducing carbon emissions.

Studies show that a 10% reduction in vehicle weight can increase EV range by 5–8%, while every 100 kg of weight reduction lowers carbon emissions by 7.5–12.5 g/km. Current vehicle body structures increasingly adopt steel–aluminum hybrid designs, hot-formed steel accounts for 64%, aluminum alloy penetration reaches 76.8%, and carbon fiber composites exceed 2.5% in high-end models.

Thermoplastic polymer materials are accelerating the replacement of metals. Average plastic usage per vehicle has increased from 150 kg in 2019 to an estimated 250 kg per NEV by 2025. High-performance thermoplastics such as PEEK and LCP are seeing annual penetration growth rates exceeding 20% in intelligent driving sensors and electronic systems.

Driven by carbon neutrality goals, automotive material development is shifting toward high-performance lightweight materials, low-carbon sustainable materials, and functionalized polymers. This article reviews the performance optimization strategies and application progress of PP, PA, PC, PBT, and PEEK, and discusses future trends under electrification, intelligence, and sustainability.

PP accounts for over 40% of total automotive plastic usage, thanks to its cost efficiency, design flexibility, and balanced mechanical properties.

Key lightweight applications include:

Interior and exterior components: Modified PP used in dashboards and door panels achieves up to 50% weight reduction compared with metal.

Structural components: Glass-fiber-reinforced PP reaches tensile strengths of 80 MPa, enabling 25% weight reduction in body panels.

Functional components: Long-glass-fiber PP used in battery trays improves impact resistance by 3×.

To meet electromagnetic shielding demands in intelligent vehicles, strontium ferrite–filled PP achieves 32 dB shielding effectiveness at 30 wt%, while reducing weight by 60% compared to metal solutions. Advanced PP/graphene/carbon nanotube composites achieve electrical conductivity above 10² S/m and shielding effectiveness up to 45 dB, representing a 200% improvement over neat PP.

Polyamide (nylon) is widely used in engine systems and electrical housings, accounting for 10–15 wt% of automotive plastics. PA components represent more than 35% of applications in intake manifolds, oil pans, and sensor housings.

Advanced reinforcement strategies include:

Carbon fiber–reinforced PA6, achieving tensile strength of 480 MPa and modulus of 47.9 GPa

Nanocellulose-grafted PA6, improving tensile strength to 108 MPa and increasing Tg to 92°C

Recycled nano-tungsten carbide–filled PA66, increasing tensile strength by 28% and HDT by 15°C

PA materials now form a three-dimensional innovation system of strength enhancement, thermal resistance, and recyclability, enabling over 40% component weight reduction.

PC accounts for 2–5 wt% of automotive plastics and is valued for high transparency and impact resistance, but its inherent brittleness limits structural use.

Recent advancements include:

Adding polyvinyl butyral (PVB) to reduce internal stress and improve environmental stress cracking resistance

Introducing 5 wt% micro-crosslinked polysiloxane, increasing notched impact strength to 75.4 kJ/m² and tensile toughness by 46.5%

Bio-based isosorbide PC, achieving over 60% elongation improvement

These developments support PC applications in panoramic sunroofs, ADAS sensor covers, and optical components.

PBT is widely used in connectors and sensors, accounting for 1–3 wt% of automotive plastics. However, hydrolysis under heat and humidity remains a challenge.

Key solutions include:

Carbodiimide hydrolysis stabilizers combined with hydrolysis-resistant glass fibers

Epoxy chain extenders and layered double hydroxides to enhance interfacial bonding

Dual-treated glass fibers enabling >85% tensile strength retention after exposure to 120°C saturated steam

These technologies support 10-year / 300,000 km durability targets for high-voltage NEV connectors.

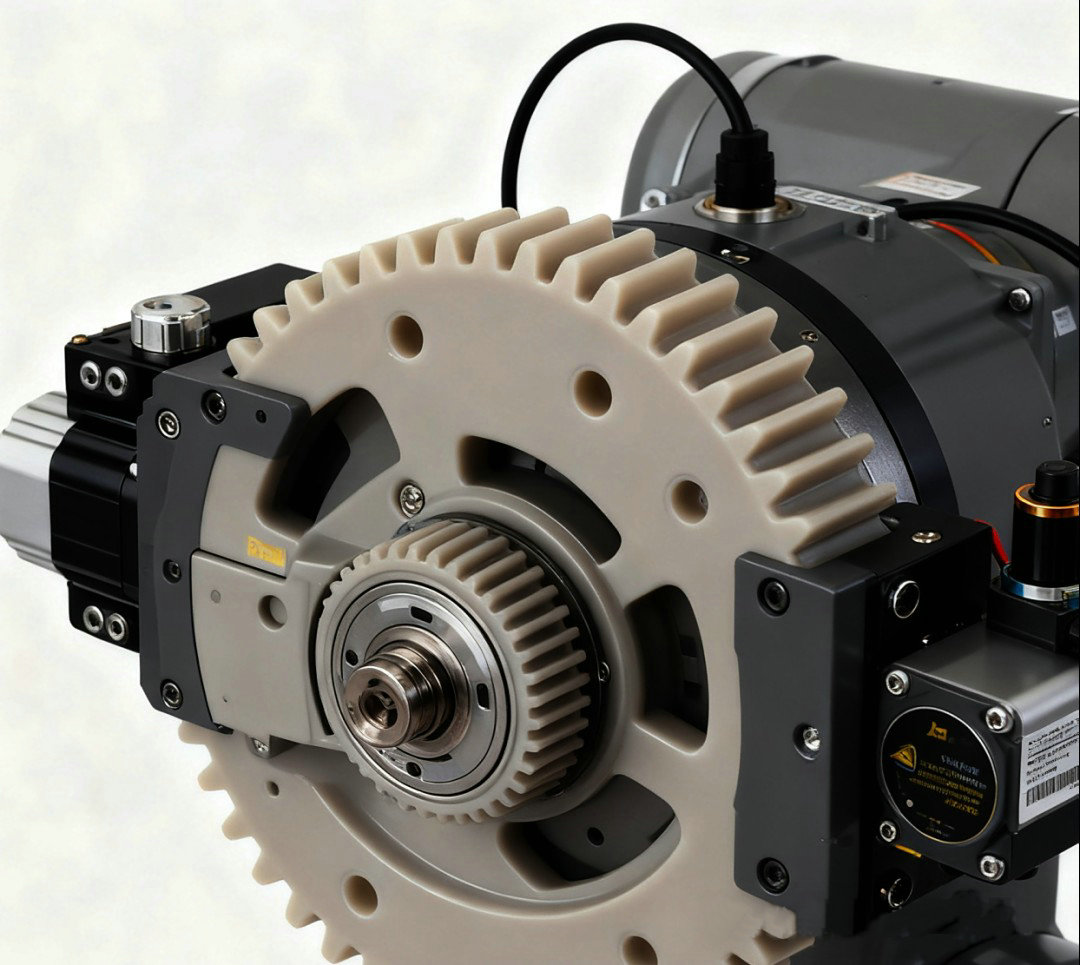

PEEK usage per vehicle is approximately 0.5–1.5 kg, mainly in high-performance applications. While PEEK offers thermal resistance (>260°C) and excellent mechanical strength, its high friction coefficient and heat dissipation limitations have constrained broader adoption.

Recent breakthroughs include:

0.25 wt% MoS₂ modification, reducing friction coefficient by 68% and improving heat dissipation by 50%

Al₂O₃–phosphate hybrid fillers, increasing compressive strength by 74.5%

Carbon nanotube–grafted interfaces raising interlaminar shear strength to 84.7 MPa

Crosslinked PEI networks increasing heat deflection temperature by 30°C

PEEK composites now form a performance matrix integrating low friction, enhanced cooling, and high toughness, enabling >100,000-hour service life in EV drive gears and robotic precision bearings.

ABS: Used in trims, grilles, mirror housings; low-odor and recyclability are key trends

PVC: Applied in seat covers, dashboards, and heat-shrink insulation for EV cables

POM: Used in gears, bearings, seatbelt buckles due to self-lubrication and fatigue resistance

LCP: Low dielectric constant and CTE make it ideal for relays, motor insulation, and battery housings

Thermoplastic polymer materials are reshaping automotive design through lightweighting, functional integration, and sustainability. With continued innovation in material modification and composite engineering, thermoplastics will play a central role in the future of electric, intelligent, and low-carbon vehicles.