Polyether Ether Ketone (PEEK) is widely recognized as one of the most advanced engineering plastics available today. Thanks to its exceptional thermal resistance, mechanical strength, chemical stability, and biocompatibility, PEEK has earned the nickname "super plastic". From aerospace and medical implants to robotics and semiconductors, PEEK is quietly reshaping high-end manufacturing.

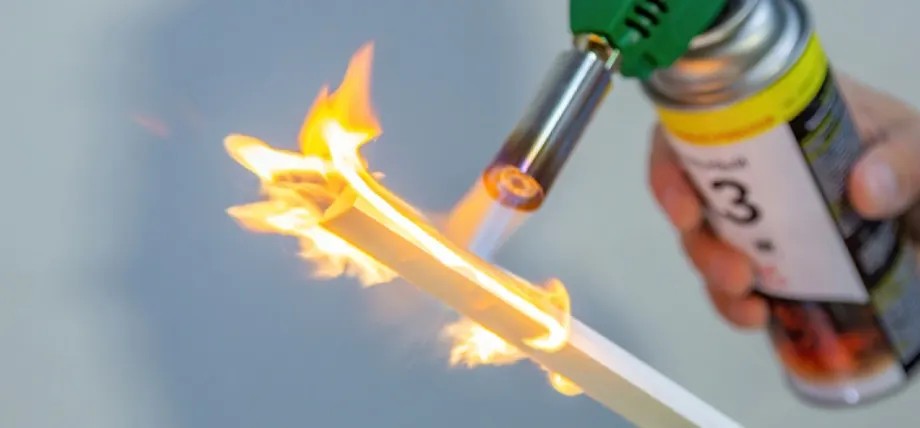

PEEK is designed to perform under the harshest conditions. It offers a continuous service temperature of 240–260°C and can withstand short-term exposure above 300°C. Even in cryogenic environments as low as −196°C (liquid nitrogen), PEEK maintains excellent toughness without embrittlement.

It is highly resistant to acids, alkalis, and most organic solvents, remaining stable in nearly all chemical environments except for strong oxidizers such as concentrated nitric acid. In addition, PEEK can endure long-term exposure to 130°C steam without degradation, making it suitable for repeated sterilization processes.

PEEK delivers outstanding mechanical performance:

Tensile strength: 90–100 MPa

Flexural strength: 130–150 MPa

Even at 200°C, PEEK retains more than 70% of its room-temperature strength. Its fatigue resistance is particularly impressive, allowing it to withstand long-term cyclic loading without cracking.

Dimensional stability is another key advantage. With a water absorption rate below 0.1%, deformation caused by temperature changes can be controlled within 0.005 mm, meeting the stringent precision requirements of high-end manufacturing and analytical instrumentation.

PEEK complies with FDA and ISO 10993 biocompatibility standards. It is non-toxic, non-allergenic, and does not trigger immune rejection, making it an ideal material for joint implants, spinal fusion cages, and dental implants.

Moreover, PEEK is compatible with common medical sterilization methods such as gamma radiation and X-ray sterilization, with no loss of performance after irradiation. Its radiolucency allows medical imaging (X-ray, CT, MRI) without interference after implantation.

With a density of only 1.32 g/cm³—less than half that of aluminum alloys—PEEK offers a specific strength up to eight times higher than aluminum. It also features self-lubricating behavior and UL94 V-0 flame retardancy without the need for additional flame-retardant additives.

PEEK is compatible with a wide range of processing methods, including injection molding, extrusion, CNC machining, and 3D printing, enabling precise fabrication of complex structural components.

In 2025, clinical trials for metal-free PEEK-OPTIMA™ femoral components in knee replacement surgeries were initiated in the United States. With an elastic modulus close to that of cortical bone, PEEK helps protect bone density and is considered by experts as "the future direction of joint replacement".

Currently, PEEK accounts for approximately 50% of the global spinal fusion device market and is widely used in dental implant abutments and surgical instrument handles.

Airbus has adopted CF/PEEK composite materials for the central hub components of the H-160 helicopter rotor, replacing traditional titanium alloys. This change significantly reduces weight while improving impact and ballistic damage resistance, enhancing survivability in harsh environments.

In high-frequency circuit boards, PEEK is increasingly replacing ceramic substrates, offering excellent insulation performance with reduced system weight.

In humanoid robot projects led by companies such as Tesla, carbon fiber reinforced PEEK is used in six-axis force sensors, reducing weight to just 58% of aluminum alloys while improving measurement accuracy. Future single-robot PEEK consumption is expected to reach 5–10 kg.

In new energy vehicles, PEEK is widely used in fuel pumps, injectors, and electrical insulation components, benefiting from its high-temperature and chemical resistance.

In the low-altitude economy and eVTOL aircraft, PEEK contributes to extended flight range through lightweight design. In the semiconductor industry, it helps mitigate electrostatic damage during wafer transport and meets high-voltage charging and high-temperature insulation requirements.

Historically, the global PEEK market has been dominated by international giants such as Victrex, with over 80% of China's demand relying on imports, making PEEK an expensive "luxury material" limited to high-end applications.

In recent years, Chinese manufacturers such as ZYPEEK and ARKPEEK | PEEKChina have broken through key technical barriers and achieved thousand-ton-level production capacity, forming the world's fourth major industrial cluster capable of large-scale PEEK manufacturing.

With domestic equipment yields exceeding 99% and continuous optimization of key raw materials such as fluoroketones, PEEK costs are steadily declining. Market forecasts suggest that China's PEEK market will reach RMB 2.18 billion by 2025 and exceed RMB 5 billion by 2031, with a compound annual growth rate of 14.4%. Emerging sectors such as humanoid robots and low-altitude aviation are expected to be the main growth drivers.

The release of GB/T 41873-2022 "Plastics—Polyether Ether Ketone (PEEK) Resin" further standardizes the industry, clearly defining technical requirements and application scopes in aerospace, medical, and automotive fields.

From a niche laboratory material to a key enabler of advanced industrial products, PEEK represents the rapid progress of new material technologies. As costs continue to decrease and applications expand, this "super plastic" is set to unlock even more possibilities.