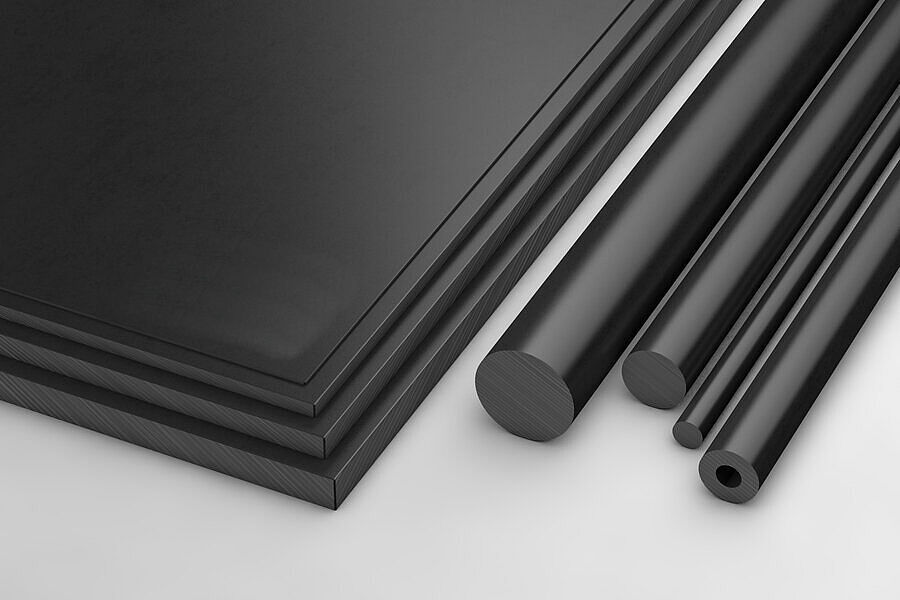

Polyether Ether Ketone (PEEK) is widely recognized as a high-performance engineering thermoplastic used in demanding applications such as aerospace, medical devices, analytical instrumentation, and semiconductor manufacturing. While natural PEEK is typically beige or off-white in color, BLACK PEEK is commonly encountered in the market. This often leads to confusion:

Is black PEEK a different material, or simply a color variation?

Using ARKPEEK® as an example, this article explains what BLACK PEEK really is, how it is produced, and why different PEEK grades appear black.

In its pure, unfilled form, standard PEEK resin is naturally beige (natural color).

For example:

ARKPEEK-1000 (Unfilled PEEK)

The standard, unmodified grade of PEEK, supplied in its natural beige color. This grade offers excellent mechanical strength, chemical resistance, and thermal stability, and is widely used for precision machined parts.

The natural color does not affect performance and is often preferred in applications where material purity or visual inspection is required.

Certain PEEK composite grades appear black by default, not because of surface coloring, but due to their internal formulation.

ARKPEEK-CF30 (30% Carbon Fiber Reinforced PEEK)

This grade is naturally black because of the carbon fiber reinforcement dispersed throughout the polymer matrix. The black color is intrinsic and uniform, directly resulting from the carbon content.

ARKPEEK-MOD (Low-Friction / Wear-Modified PEEK)

Modified PEEK grades often contain PTFE, graphite, or other solid lubricants, which give the material a black or dark appearance. Again, this black color comes from the formulation itself, not from dyes.

In these cases, black is the natural color of the material, and no additional pigmentation is required.

In addition to naturally black composite grades, black PEEK can also be achieved by pigmentation.

ARKPEEK-1000 (Unfilled PEEK)

ARKPEEK-GF30 (30% Glass Fiber Reinforced PEEK)

Both grades are naturally beige or light in color, but can be compounded with black pigment to meet customer requirements. This process does not change the fundamental mechanical, thermal, or chemical properties of the PEEK material when properly controlled.

Black-colored PEEK is often chosen for:

Visual consistency across assemblies

UV light absorption

Improved appearance of machined parts

Industry-specific color standards

While black is the most common custom color, PEEK is not limited to black.

ARKPEEK materials can be custom-colored according to color cards or specific requirements, including:

Grey

Blue

Green

Red

Other designated industrial colors

Color customization is typically achieved during compounding and is suitable for applications where part identification, branding, or system differentiation is required.

In general:

Color itself does not define PEEK performance

Mechanical strength, temperature resistance, wear behavior, and chemical compatibility depend on material grade and formulation, not color

However, it is important that pigmentation is properly controlled, especially for:

Precision components

Medical or analytical applications

Tight dimensional tolerances

This is why engineered materials like ARKPEEK® offer color customization while maintaining consistent material properties.

BLACK PEEK can mean different things depending on the grade:

CF30 and MOD PEEK → Naturally black due to formulation

Unfilled and GF30 PEEK → Black achieved through pigmentation

Black does not automatically indicate reinforcement or modification

Custom colors are available beyond black

Understanding the reason behind PEEK color helps engineers and buyers make the correct material selection based on performance—not appearance alone.