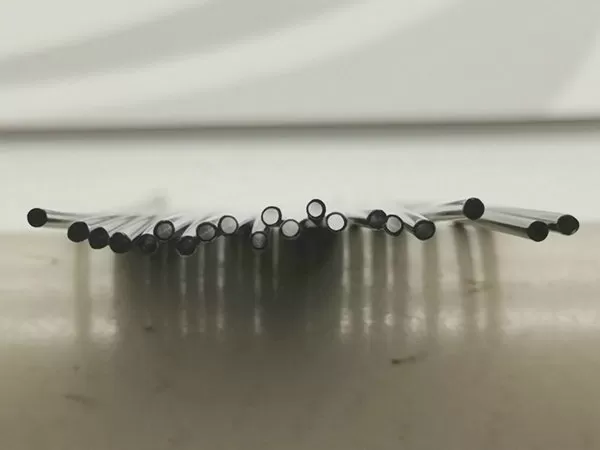

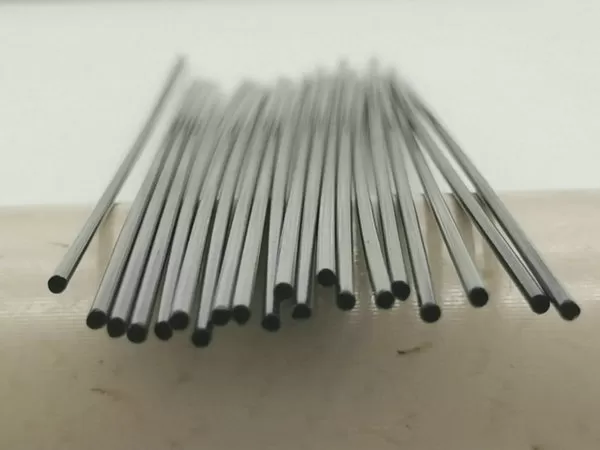

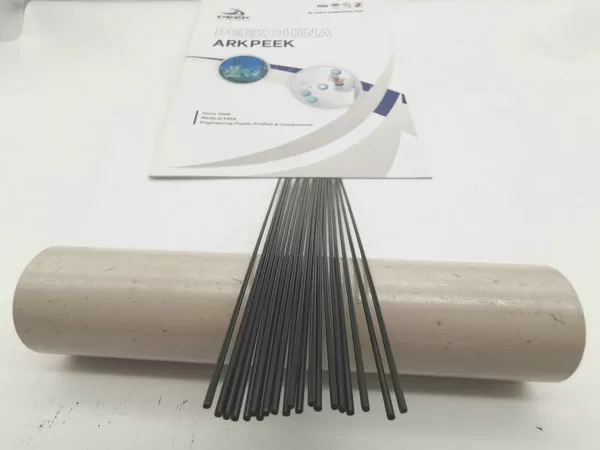

Black Color PEEK Tubing

Our black PEEK tubing is the perfect solution for medical devices, offering excellent biocompatibility, durability, and resistance to high temperatures, chemicals, and radiation. Made from high-quality polyetheretherketone (PEEK) material, our tubing is reliable and versatile, making it ideal for a wide range of applications. Our black PEEK tubing is available in custom sizes to meet your specific needs. Choose our black PEEK tubing for your next project and experience the benefits of high-quality tubing that meets your exact specifications. Whether you're looking for tubing for catheters, surgical instruments, or other medical devices, our black PEEK tubing is a reliable and durable solution that you can count on.

Key Features of Black Medical Colored PEEK Tubing:

• Ultra hard material

• Very good chemical resistance

• Stable at temperatures up to 228°C

• Excellent abrasion resistance

• Flame retardant (UL94 V-0)

• Very tight dimensional tolerances

PEEK Tubing Black Colored:

• In coils, on spools or straight lengths with clean, square cuts

• Translucent or Opaque

• Wall thickness varying along length (Bumped tubing)

• Coloured PEEK tubing

• Multi-Layer PEEK tubing

• Reinforced PEEK tubing (Stainless Steel Wires)

• Shaped tubing

| Medical Polymer PEEK Tubing Datasheet | ||||||

| Property | Reference Standard | Test Method | Unit | Specification | Result | |

| Physical Properties | Glass Transition | ASTM F2026 | ASTM D3418 | °C | 125-165 | 147 |

| Temperature, Tg | ||||||

| Melt Temperature, Tm | ASTM F2026 | ASTM D3418 | °C | 320-360 | 338 | |

| Recrystallization | ASTM F2026 | ASTM D3418 | °C | 260-320 | 289 | |

| Temperature, Tc | ||||||

| Viscosity | ASTM F2026 | ISO 11443 | Pa·s | 400-480 | 437 | |

| Infrared Spectrum | ASTM F2026 | ASTM F1579 | / | See Appendix X1 | See Appendix X2 | |

| Density | ASTM F2026 | ASTM D1505 | kg/m3 | 1280-1320 | 1294 | |

| Chemical Properties | Total Heavy Metals (Ag, As, Bi, Cd, Cu, Hg, Mo, Pb, Sb, and Sn), max | ASTM F2026 | US Pharmacopeia, | ppm | <100 | <10 |

| Test 233 | ||||||

| Mechanical Properties | Tensile Strength at Yield (zero slope), min | ASTM F2026 | ASTM D638, Type IV, 5.08 cm/min | MPa | 90 | 105 |

| Tensile Strength at Break, min | ASTM F2026 | ASTM D638, Type IV, 5.08 cm/min | MPa | 70 | 80 | |

| Elongation at Break, min | ASTM F2026 | ASTM D638, Type IV, 5.08 cm/min | % | 5 | 18 | |

| Flexural Strength, min | ASTM F2026 | ASTM D790 | MPa | 110 | 163 | |

| Flexural Modulus, min | ASTM F2026 | ASTM D790 | GPa | 3 | 4 | |

| Impact Strength, | ASTM F2026 | ISO 180 | kJ/m2 | 4 | 9 | |

| Notched Izod, min | ||||||

| Biological Properties | Genotoxicity | ISO 10993-3 | ISO 10993-3 | / | Negative | Negative |

| Animal Intracutaneous (Intradermal) Reactivity | ISO 10993-10 | ISO 10993-10 | / | ≤1 | 0 | |

| Skin Sensitization | ISO 10993-10 | ISO 10993-10 | / | ≤1 | 0 | |

| Acute Systemic Toxicity | ISO 10993-11 | ISO 10993-11 | / | No Acute Systemic Toxicity | No Acute Systemic Toxicity | |

| Subchronic Systemic Toxicity | ISO 10993-11 | ISO 10993-11 | / | No Subchronic Systemic Toxicity | No Subchronic Systemic Toxicity | |

| local Effects After Implantation | ISO 10993-6 | ISO10993-6 | / | No obvious difference between the test sample and the control sample | No obvious difference between the test sample and the control sample | |

| In Vitro Cytotoxicity | ISO 10993-5 | ISO10993-5 | / | ≤1 | 1 | |

| Evaluation of Haemolytic Properties | ISO 10993-4 | ISO10993-4 | % | <5 | 1 | |

| Material Mediated Pyrogens | ISO 10993-11 | ISO 10993-11 | / | No Pyrogenic Responses | No Pyrogenic Responses | |

| Extractables of The Material | ISO 10993-18 | ISO 10993-18 | μg/g | The contents of Phenyl Sulfone≤300 | The contents of Phenyl Sulfone<0.09 | |