In the ever-evolving aerospace industry, the quest for high-performance materials is paramount to ensure the safety and efficiency of aircraft. Polyetheretherketone (PEEK), a remarkable thermoplastic, has emerged as a game-changer with its exceptional thermal properties. This article explores the advantages of harnessing PEEK’s thermal prowess in aerospace applications, revolutionizing the way aircraft components perform.

1, Enhancing Aircraft Reliability: Unveiling PEEK’s Thermal Resilience The extreme conditions experienced by aircraft, including high temperatures and pressures, demand materials that can withstand the heat. PEEK’s remarkable ability to maintain its mechanical properties at elevated temperatures makes it an ideal choice for critical aerospace components. Discover how PEEK’s thermal resilience keeps aircraft in optimal condition for flight, ensuring reliable performance.

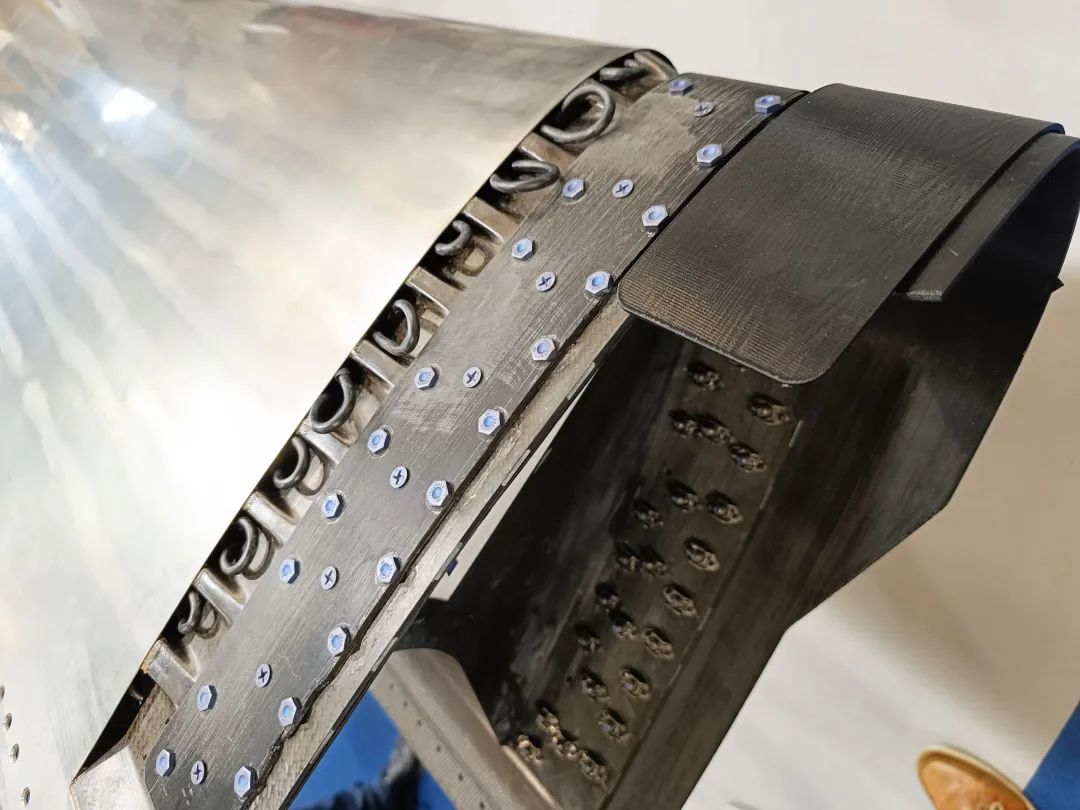

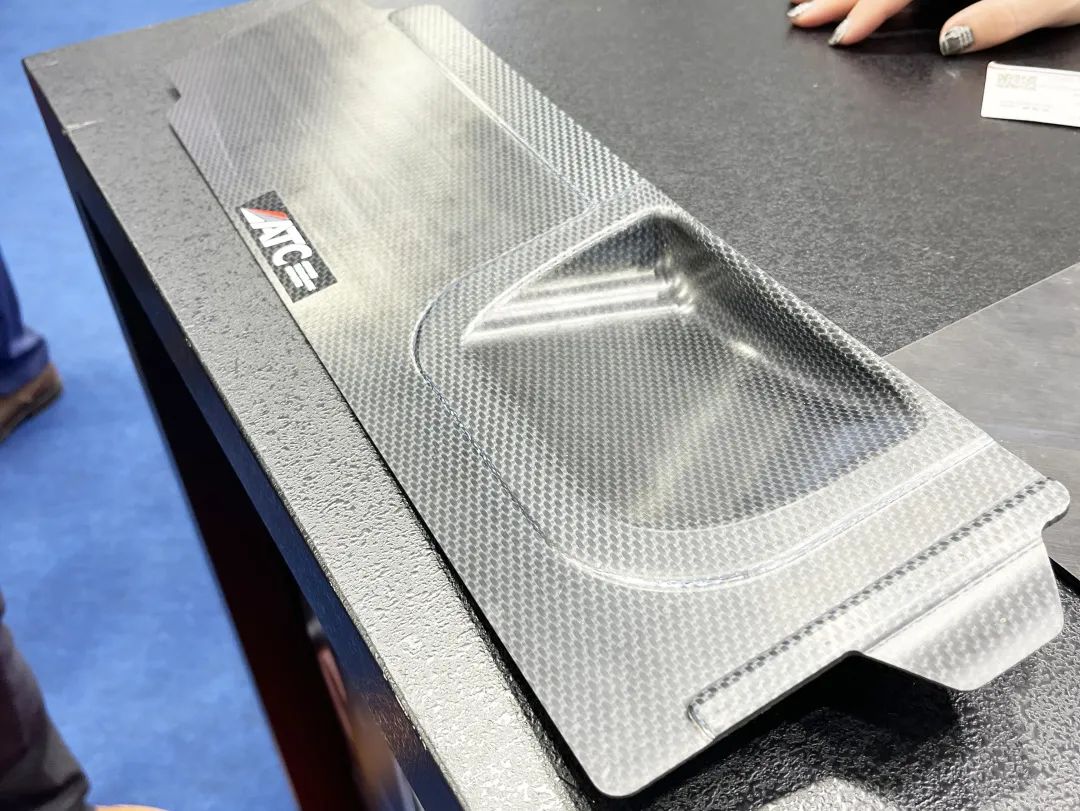

2, PEEK’s Versatility in Aerospace Manufacturing Delve into the wide range of applications for PEEK in aerospace manufacturing beyond just machined aircraft components. From flight control systems and fuel systems to aircraft interiors and engine components, PEEK’s versatility shines through. Explore the diverse possibilities of integrating PEEK into various aerospace applications, unlocking new levels of performance.

3, Fueling Efficiency: The Energy-saving Potential of PEEK In addition to its thermal advantages, PEEK’s lightweight nature plays a pivotal role in enhancing fuel efficiency. By substituting traditional metal components with high-performance polymers like PEEK, aircraft weight is significantly reduced, resulting in lower fuel consumption and reduced emissions. Uncover how PEEK’s weight-saving capabilities contribute to greener, more cost-effective aviation.

4, Empowering Aerospace Manufacturing: Selecting the Right Partner Choosing the right machining facility is crucial for successful aerospace manufacturing. Learn about the essential considerations when selecting a partner, such as expertise in machining plastics, adherence to stringent regulatory standards, and effective communication throughout the process. Discover the importance of partnering with a reliable and experienced facility to ensure top-quality PEEK components.

The advantages of PEEK’s thermal properties in aerospace applications are undeniable. Its ability to withstand extreme temperatures, coupled with its versatility and lightweight characteristics, positions PEEK as a leading material in the industry. By leveraging PEEK’s thermal resilience, aerospace manufacturers can enhance aircraft reliability, fuel efficiency, and overall performance. When selecting a machining facility, it is imperative to choose a trusted partner who understands the intricacies of working with PEEK and adheres to rigorous industry standards. Embrace the power of PEEK and unlock new possibilities in aerospace manufacturing.