Introduction:

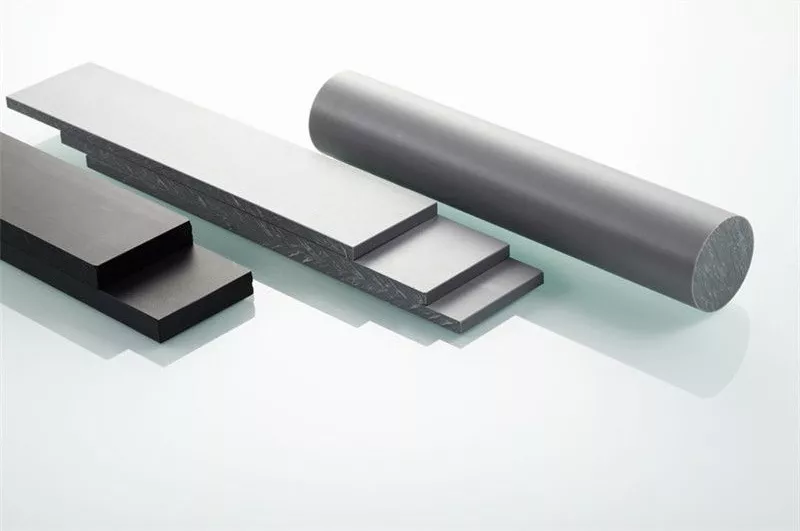

Polyetheretherketone (PEEK) and carbon-filled PEEK (CF) are two distinct variants of a high-performance thermoplastic polymer known for their exceptional mechanical, thermal, and chemical properties. When selecting between pure PEEK and CF, it is crucial to consider the specific engineering conditions and requirements. This article aims to provide insights into when to choose pure PEEK and when to opt for CF, highlighting their performance in different engineering applications.

Pure PEEK:

Pure PEEK is the unfilled form of the polymer, offering a unique set of characteristics. Here are scenarios where pure PEEK is typically preferred:

a. High-Temperature Applications:

Pure PEEK exhibits excellent thermal stability, withstanding temperatures up to 250°C (482°F) for prolonged periods. It is an ideal choice for applications involving exposure to high temperatures, such as aerospace components, automotive engine parts, and downhole oil and gas equipment.

b. Chemical Compatibility:

Pure PEEK demonstrates outstanding chemical resistance, making it suitable for applications where exposure to harsh chemicals, solvents, and acids is expected. It finds use in chemical processing, semiconductor manufacturing, and pharmaceutical industries.

c. Electrical Insulation:

With excellent electrical insulation properties, pure PEEK is commonly utilized in electrical and electronics applications. It serves as an insulator in connectors, coil forms, circuit boards, and other components requiring reliable electrical performance.

d. FDA Compliance:

Pure PEEK is FDA compliant and exhibits excellent biocompatibility, making it suitable for medical and dental applications. It is used in implants, surgical instruments, and medical device components.

Carbon-Filled PEEK (CF):

CF refers to PEEK infused with carbon fiber or graphite, enhancing its properties. Consider the following conditions where CF is often preferred:

a. Increased Mechanical Strength:

The addition of carbon fibers or graphite enhances CF’s mechanical strength, stiffness, and wear resistance. CF is a suitable choice for applications requiring higher load-bearing capabilities, such as gears, bearings, seals, and structural components in automotive, aerospace, and industrial equipment.

b. Improved Tribological Performance:

CF offers improved tribological properties, including lower friction and reduced wear. It is commonly chosen for applications involving sliding or rotating components, such as bushings, thrust washers, and pump components.

c. EMI/RFI Shielding:

Carbon-filled PEEK exhibits excellent electrical conductivity, making it an effective material for EMI/RFI shielding applications. It finds use in electronic enclosures, connectors, and aerospace equipment to prevent electromagnetic interference.

d. Enhanced Thermal Conductivity:

The presence of carbon fibers or graphite in CF imparts improved thermal conductivity compared to pure PEEK. This property is valuable in heat management applications, such as heat exchanger components, thermal insulators, and electronic cooling systems.

Conclusion:

Selecting between pure PEEK and carbon-filled PEEK (CF) depends on the specific engineering conditions and requirements. Pure PEEK is often chosen for its high-temperature resistance, chemical compatibility, electrical insulation, and FDA compliance. On the other hand, CF offers increased mechanical strength, improved tribological performance, EMI/RFI shielding capabilities, and enhanced thermal conductivity. By considering these factors, engineers can make informed decisions when selecting the most appropriate material for their applications, ensuring optimal performance and durability.