In discussions about material selection for "plastic replacing steel", one concept is often overlooked yet critically important: material performance should not be judged by absolute values alone. When we talk about plastic replacing steel, we are not truly comparing "which material is harder or stronger", but rather which material can carry more load and maintain higher stiffness at the same weight. This is where specific strength and specific stiffness become essential.

Steel typically has a strength of 400–1000 MPa, while common engineering plastics range from several tens to a few hundred MPa. At first glance, plastics appear incomparable. However, when strength is converted to "stress per unit weight", the picture changes entirely.

Plastics have a density of only 1.0–1.5 g/cm³, while steel reaches 7.8 g/cm³. In lightweight design, the true constraint is not whether a material can withstand the load, but whether the structure's weight can be reduced.

With the same mass, plastics can occupy a much larger volume, which means:

A larger section moment of inertia (beneficial for stiffness)

A larger load-bearing area (beneficial for strength)

Therefore, the starting point for plastic replacing steel must be:

Specific strength = σ / ρ

Specific stiffness = E / ρ

Ignoring density is equivalent to ignoring lightweight design itself. Once density is considered, some plastic products can even outperform titanium in specific performance.

Specific strength (σ/ρ): The maximum stress a material can withstand per unit weight. It determines load-bearing capacity at equal weight. For example, carbon-fiber-reinforced PA can reach a specific strength of about 100 MPa·cm³/g, comparable to some aluminum alloys.

Specific stiffness (E/ρ): The stiffness provided per unit weight. It determines deformation under equal weight, which is especially important for brackets, housings, and frame components. Higher specific stiffness means deformation remains controllable while reducing weight.

In plastic replacing steel, three core factors guide material selection:

Density (ρ): Steel is high, plastics are low — enabling volume expansion and shape compensation.

Strength (σ): Steel is high, plastics are moderate — specific strength can be comparable.

Stiffness (E): Steel is high, plastics are lower — structural design (ribs, reinforcements, fillers) can compensate.

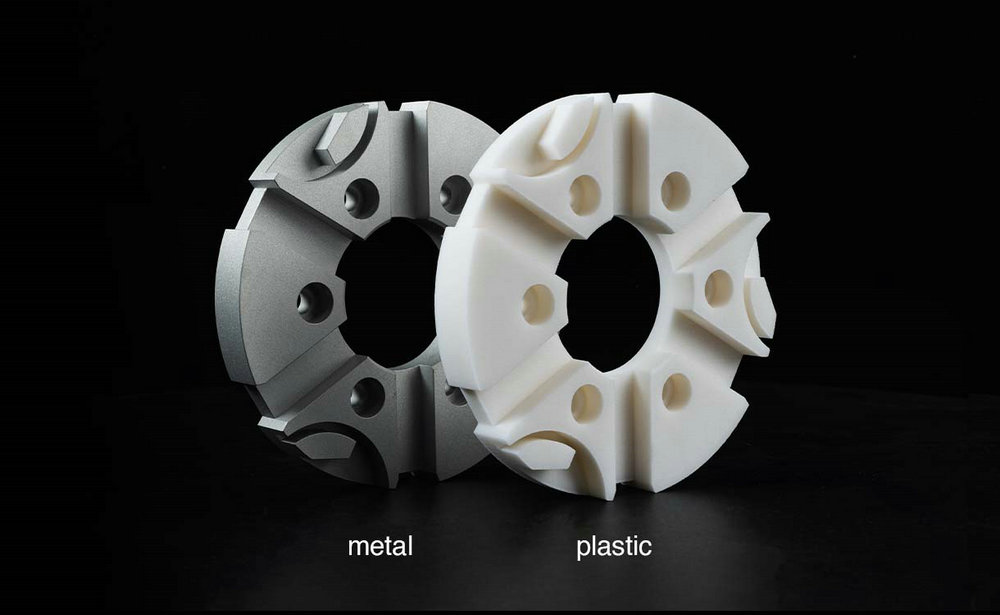

In other words, plastics are not stronger, but still strong enough after becoming lighter. Plastic replacing steel is not about replacing shapes one-to-one, but about reconstructing performance equivalence.

Thus, the correct question is not:

"Is this plastic as strong as steel?"

But rather:

"At equal weight or structural conditions, can its specific strength and stiffness meet the design requirements?"

Assume a 1 kg bracket:

Steel volume: approximately 0.13 L

GF-PA6 (density 1.35 g/cm³): volume expands to about 0.74 L at the same weight

The nearly sixfold volume increase allows ribs, reinforcements, and higher inertia moments. As a result, overall stiffness and strength can fully match the original steel part, while weight is reduced by 60–70%.

The essence of plastic replacing steel is not making plastics become steel, but leveraging superior specific performance under weight-limited design constraints. That is why specific strength and specific stiffness are not marketing terms, but fundamental engineering logic.