In high-pressure, high-temperature, and chemically aggressive environments, valve seat material selection directly impacts system reliability, sealing integrity, and service life.

A PEEK valve seat offers a high-performance alternative to traditional PTFE, nylon, and even metal seating solutions, particularly in demanding industrial applications.

This technical guide explains why PEEK has become one of the most trusted engineering plastics for valve seat manufacturing.

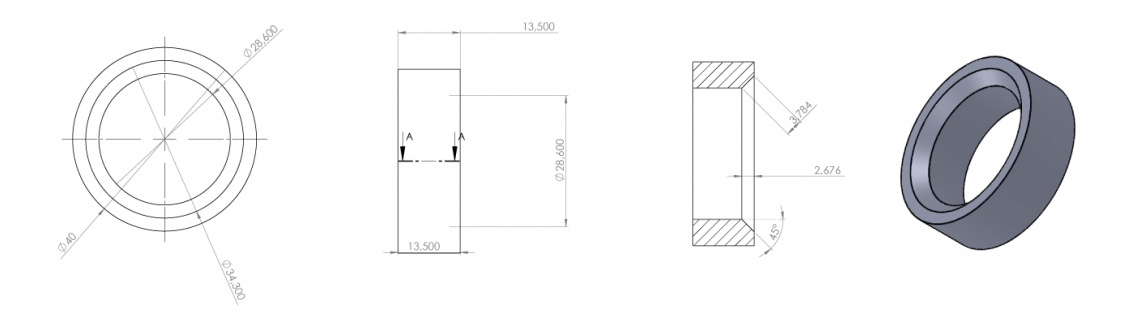

A PEEK valve seat is a precision-machined sealing component manufactured from polyether ether ketone (PEEK), a high-performance thermoplastic known for its exceptional mechanical and chemical properties.

Valve seats are critical sealing interfaces inside:

Ball valves

Check valves

Control valves

Needle valves

High-pressure instrumentation valves

In these systems, the seat must withstand compressive loads, friction, temperature cycling, and chemical exposure without deformation or leakage.

PEEK maintains continuous working temperatures up to 250°C (482°F) and short-term exposure above 300°C.

Unlike PTFE, which softens under heat, PEEK maintains structural integrity and load-bearing capacity.

PEEK exhibits excellent wear performance and low friction characteristics, making it suitable for dynamic sealing applications where repetitive motion occurs.

This reduces:

Surface damage

Particle generation

Premature leakage

PEEK resists:

Acids

Bases

Hydrocarbons

Steam

Solvents

This makes PEEK valve seats ideal for chemical processing, oil & gas systems, and aggressive fluid control applications.

One of the main failure modes in valve seats is creep deformation under long-term load.

PEEK offers:

High compressive strength

Excellent dimensional stability

Low creep under continuous stress

This ensures long-term sealing reliability in high-pressure systems.

| Property | PEEK | PTFE | Nylon | Metal |

| Temperature Resistance | Excellent | Moderate | Limited | Excellent |

| Wear Resistance | High | Low | Moderate | Very High |

| Chemical Resistance | Excellent | Excellent | Moderate | Variable |

| Creep Resistance | Very Low | High | Moderate | Very Low |

| Weight | Lightweight | Lightweight | Lightweight | Heavy |

Compared to PTFE, a PEEK valve seat provides significantly better mechanical strength and dimensional stability.

Compared to metal seats, PEEK reduces weight, prevents galling, and provides better chemical resistance without corrosion risk.

PEEK valve seats are widely used in:

Oil & Gas high-pressure valves

Chemical processing systems

Semiconductor fluid control systems

Analytical instrumentation

Medical and pharmaceutical processing equipment

High-temperature steam systems

In these industries, material failure is not an option - reliability is critical.

Most industrial PEEK valve seats are CNC machined from extruded PEEK rod. This ensures:

High dimensional accuracy

Custom sizing

Tight tolerance control

For larger diameter seats or special geometries, machining from PEEK plate is preferred.

For high-volume applications, injection molded PEEK valve seats may be used, although machining provides better precision for industrial-grade components.

Different grades of PEEK are available depending on performance requirements:

Best for chemical resistance

General industrial sealing

Higher stiffness

Lower thermal expansion

Ideal for high-pressure systems

Improved dimensional stability

Enhanced mechanical strength

Improved wear and friction performance

Extended service life in dynamic applications

Material selection depends on:

Operating temperature

System pressure

Media type

Motion frequency

Typical values (Virgin PEEK):

Continuous use temperature: 250°C

Tensile strength: ~90–100 MPa

Compressive strength: >110 MPa

Density: 1.30 g/cm³

Coefficient of friction: 0.30–0.40

These properties make PEEK one of the most reliable engineering thermoplastics for valve seat manufacturing.

For industrial OEMs and valve manufacturers, custom PEEK valve seat production includes:

Precision CNC machining

Tight tolerance control

Custom geometry design

Small batch & high-volume production

Material traceability

A professional PEEK valve seat manufacturer should offer:

Technical material consultation

Application-specific grade recommendation

Engineering drawing support

Stable raw material sourcing

When performance, reliability, and longevity are critical, a PEEK valve seat provides a superior solution compared to traditional polymer or metal seating materials.

Its combination of:

High temperature stability

Excellent wear resistance

Strong chemical resistance

Low creep under load

makes it one of the most advanced materials available for industrial valve sealing systems.

For high-pressure, aggressive, and precision-controlled environments, PEEK is not just an alternative - it is often the optimal engineering choice.