In advanced electronic packaging and thermal management systems, engineers constantly face a difficult challenge:

Is it possible to find a material that conducts heat like metal, insulates like ceramic, and processes like an engineering plastic?

For years, this "all-in-one" requirement has created a major materials dilemma.

Known as the "plastic gold", Polyether Ether Ketone (PEEK) has been widely used in aerospace, new energy vehicles, medical devices, and semiconductor applications due to its:

Outstanding high-temperature resistance

Excellent mechanical strength

Superior chemical stability

Intrinsic electrical insulation

However, despite being a high-performance champion, PEEK has one critical limitation:

Extremely low thermal conductivity

PEEK is a semi-crystalline aromatic thermoplastic with a dense and highly ordered molecular structure. While this structure gives it excellent overall performance, it severely limits phonon transport (the primary heat carriers in polymers).

Pure PEEK has a thermal conductivity of only:

0.21 W/(m·K)

This becomes a major problem in high power-density electronics such as:

High-performance CPUs

High-power LEDs

IGBT modules

If heat cannot be dissipated efficiently, device junction temperature rises rapidly, leading to performance degradation, reduced reliability, and even permanent failure.

The industry urgently needs:

A PEEK-based composite that achieves BOTH high thermal conductivity AND electrical insulation.

Yet improving PEEK's thermal conductivity has historically been extremely challenging.

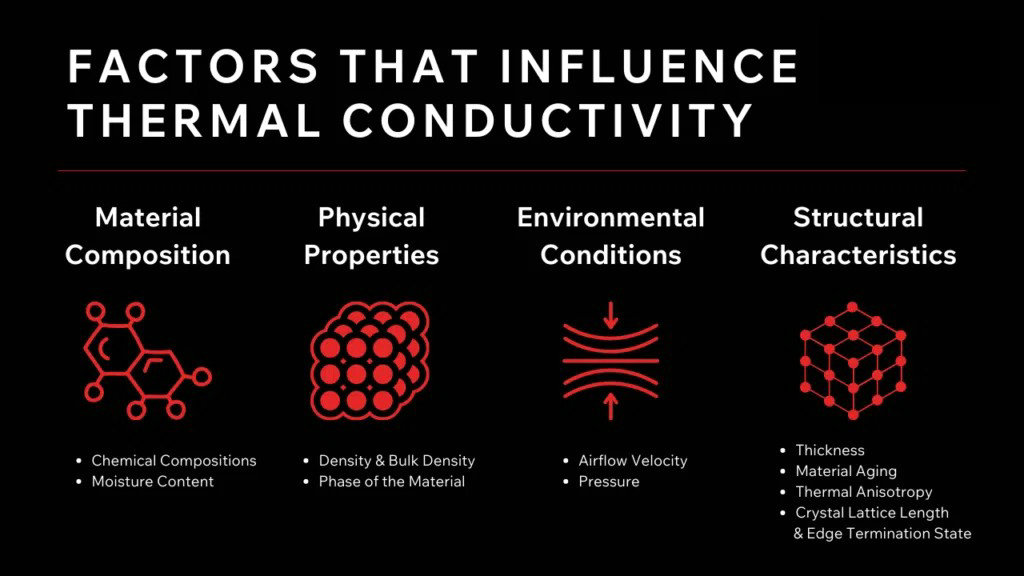

The most effective way to improve polymer thermal conductivity is by adding high-conductivity fillers such as:

Boron nitride nanosheets (BNNSs)

Carbon nanotubes (CNTs)

However, PEEK has extremely high melt viscosity. Traditional melt blending methods result in:

Poor filler dispersion

Random agglomeration

No continuous heat conduction network

Even with 30 wt% boron nitride via melt blending, thermal conductivity only increases to around:

~1.01 W/(m·K)

This improvement is limited and insufficient for demanding electronic applications.

Electrospinning is a powerful method for building highly oriented filler networks because it:

Uses electric field stretching

Aligns fillers along fiber axes

Creates directional heat pathways

However, PEEK is nearly insoluble in common solvents (except concentrated sulfuric acid), making electrospinning practically impossible.

Ironically, the same chemical stability that makes PEEK excellent for harsh environments also prevents solution-based microstructure design.

Instead of struggling within traditional melt blending, researchers developed an elegant solution:

Temporarily modify PEEK into a soluble precursor → Build oriented networks → Restore it back to original PEEK.

This three-step innovation includes:

Researchers synthesized a soluble polymer precursor called PEEKt (poly(arylene ether ketimine)) via Schiff base reaction.

In PEEKt:

Ketone groups (C=O) are replaced with ketimine groups (C=N)

The material becomes soluble in NMP solvent

Electrospinning becomes feasible

This allows precise microstructure engineering.

Functionalized fillers were added:

Hydroxylated BNNSs

Carboxylated multi-walled carbon nanotubes (MWCNTs)

Optimized ratio:

fBNNSs : fMWCNTs = 25 : 1

During electrospinning:

High-aspect-ratio MWCNTs act as "thermal bridges"

BN nanosheets align along fiber direction

A 3D interconnected thermal skeleton forms

The composite nanofiber membrane undergoes acid hydrolysis:

10 wt% sulfuric acid

100°C

24 hours

This process converts C=N back to C=O, fully restoring the original PEEK structure (APEEKt).

Crucially:

Fiber morphology is preserved

Filler orientation remains intact

Thermal network stays continuous

Final hot pressing:

Increases compactness

Solidifies thermal pathways

Produces high-performance PEEK composite sheets

With 25 wt% fBNNSs:

In-plane thermal conductivity = 5.09 W/(m·K)

→ 24.2× higher than pure PEEK

With hybrid fillers (25:1 ratio):

In-plane thermal conductivity = 6.02 W/(m·K)

→ 28.7× improvement

→ 1.2× higher than single-filler system

Electrospun samples significantly outperform solution-cast samples, proving that filler orientation is critical.

Despite adding conductive CNTs:

Volume resistivity remains ~10¹⁶ Ω·cm

Far above insulation threshold (10⁹ Ω·cm)

The CNT content is below percolation threshold, functioning only as thermal bridges-not electrical pathways.

5% weight loss temperature (T5%) exceeds: 556°C

Thermal stability remains consistent with native PEEK.

Infrared imaging confirms:

Faster heating response

Faster cooling cycles

Stable repeated performance

After 180 seconds heating:

Composite: 79.7°C

Pure PEEK: 57.5°C

Clear evidence of superior thermal management.

This new-generation PEEK composite combines:

6.02 W/(m·K) thermal conductivity

10¹⁶ Ω·cm insulation

High thermal stability

Mechanical robustness

Ideal applications include:

Efficient heat removal + absolute insulation.

Widely used in:

Electric vehicles

Rail transit systems

Replacing brittle ceramic substrates with machinable, impact-resistant alternatives.

RF module insulation + heat spreading.

Lightweight + reliable + high-temperature resistant.

This innovative "Electrospinning + Acid Restoration + Hot Pressing" strategy solves a long-standing contradiction in PEEK modification:

Achieving high thermal conductivity without sacrificing insulation.

More importantly, it provides a new paradigm for functionalizing other high-performance but difficult-to-process polymers.

For manufacturers and engineers developing next-generation electronic thermal management materials, this approach represents not just a material upgrade—but a technological roadmap toward future high-performance composites.