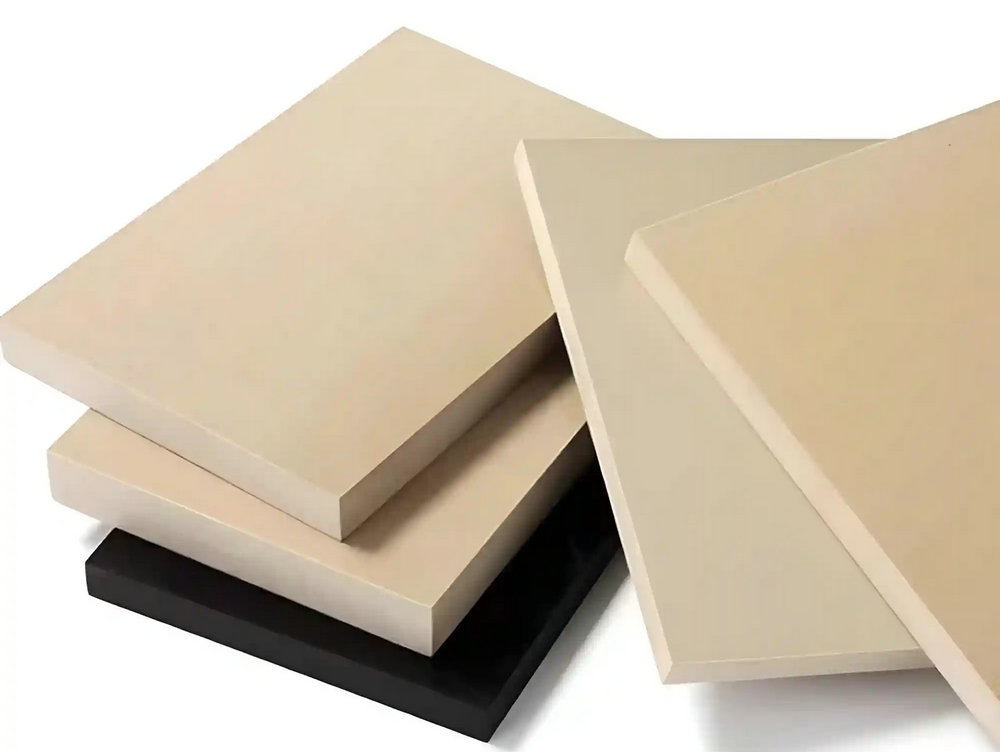

PEEK plate is a high-performance engineering plastic sheet manufactured from Polyether Ether Ketone (PEEK), one of the most advanced thermoplastic polymers available today. Known for its exceptional heat resistance, mechanical strength, and chemical stability, PEEK plate is widely used in demanding industries such as aerospace, semiconductor, medical, oil & gas, and precision engineering.

Compared to standard engineering plastics, PEEK plate offers:

Continuous service temperature up to 260°C (500°F)

Excellent wear and friction performance

High dimensional stability

Outstanding chemical resistance

Superior mechanical strength

PEEK plate is typically produced through compression molding or extrusion and supplied in various thicknesses for machining applications.

PEEK plate is often selected to replace metal, PTFE, PPS, or other engineering plastics when performance is critical.

Continuous use temperature: 260°C

Short-term temperature resistance: up to 300°C

Low thermal expansion

High tensile strength

Excellent flexural modulus

Outstanding creep resistance

Resistant to acids, bases, hydrocarbons

Suitable for aggressive chemical environments

Low moisture absorption

Excellent abrasion resistance

Ideal for sliding and structural components

Good dielectric properties

Suitable for semiconductor and electronics applications

As a professional PEEK plate supplier serving the US and European markets, we maintain large stock inventory to ensure fast delivery and stable supply.

3mm – 100mm

300mm

610mm

1000mm

Precision saw cutting

CNC pre-machining

Tight tolerance thickness control

We support low minimum order quantities and fast global shipping to North America and Europe.

To meet different application requirements, PEEK plate is available in multiple grades:

High purity

Excellent chemical resistance

Ideal for medical and semiconductor use

30% carbon fiber reinforcement

Higher stiffness and strength

Lower thermal expansion

Suitable for structural and load-bearing parts

30% glass fiber filled

Improved dimensional stability

Cost-effective structural solution

Enhanced tribological performance

Suitable for bearings, wear pads, and sliding components

PEEK plate is widely used across high-performance industries:

Structural brackets

Lightweight replacement for aluminum

Thermal insulation parts

Wafer handling components

Insulation plates

High-purity fixtures

Surgical instrument components

Sterilizable structural parts

Radiolucent medical parts

Seal rings

Compressor components

Downhole equipment parts

High-strength lightweight parts

Precision structural components

| Material | Continous Temp | Strength | Chemical Resistance | Cost |

| PEEK Plate | 260°C | Very High | Excellent | High |

| PTFE | 260°C | Low | Excellent | Medium |

| PPS | 220°C | Medium | Very Good | Medium |

| POM | 100°C | Medium | Moderate | Low |

PEEK plate is selected when long-term mechanical strength at high temperatures is required.

PEEK plate is highly suitable for CNC machining. Due to its mechanical stability and predictable cutting behavior, it can be processed into:

Precision gears

Seal rings

Valve components

Structural frames

Insulation parts

For thick plates, stress-relief annealing before machining is recommended to ensure dimensional stability.

Our custom machining services include:

CNC milling

CNC turning

Drilling & tapping

Tight tolerance finishing

When selecting PEEK plate, consider:

Operating temperature

Mechanical load requirements

Wear resistance needs

Chemical exposure

Dimensional stability requirements

Regulatory requirements (FDA, medical grade)

If stiffness and strength are critical → choose CF30 PEEK plate

If chemical resistance and purity are critical → choose natural PEEK

If wear resistance is key → choose modified PEEK

For customers in Europe and North America, supply stability is crucial.

Working with a reliable PEEK plate stock supplier ensures:

Fast lead times

Stable raw material batches

Consistent quality

Flexible custom cutting

Reduced downtime

We maintain multi-size inventory and provide custom machining solutions for industrial OEM customers.

Continuous use up to 260°C, with short-term exposure up to 300°C.

Yes, especially in applications requiring lightweight, corrosion resistance, and thermal stability.

Yes. It offers excellent machinability and dimensional stability.

Typically from 3mm to 100mm, with custom thickness options available.