PEEK injection molded parts typically show a primary molding shrinkage of about 1.0–2.0%, with unfilled grades around 1.0–1.8% and filled grades often below 1.0%; however, additional post-mold shrinkage can occur over hours to weeks as crystallinity continues to develop, especially if the molding or service temperature approaches PEEK's crystallization window. Understanding both immediate and post-shrinkage, and tuning gate design, packing, and mold temperature, is essential for holding tight tolerances in high-precision PEEK components.

PEEK is a semi-crystalline polymer with typical crystallinity of about 30–40%, and this crystalline structure is the root cause of its relatively high and directional shrinkage.

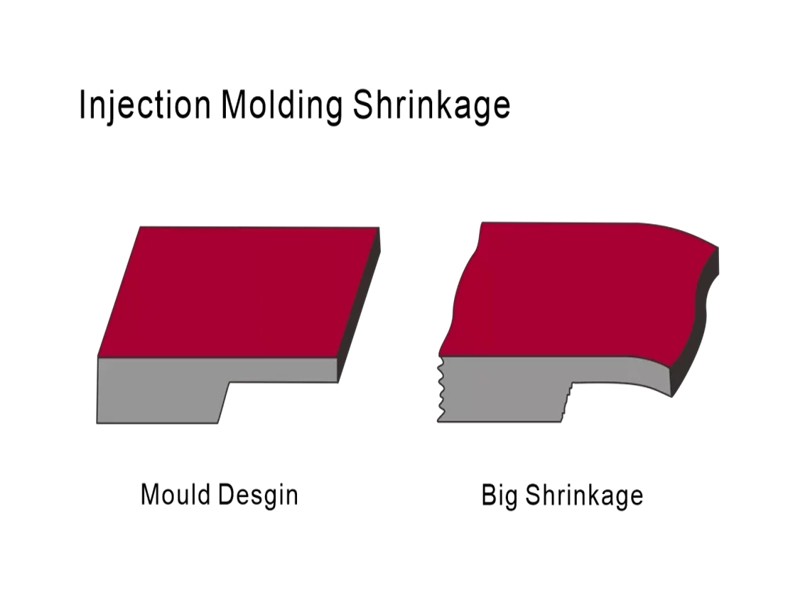

During cooling from the melt, molecular chains pack into crystalline regions and the volume contracts, leading to molding shrinkage that is higher than common amorphous plastics.

Molding shrinkage is the size reduction that occurs from melt filling at high temperature and pressure to ejection at mold temperature; unfilled PEEK usually shrinks about 1.0–1.8%, while glass- or carbon-filled grades can shrink as low as about 0.3–0.9% depending on orientation.

Post-shrinkage (secondary shrinkage) happens after ejection as the part equilibrates and crystallization continues, especially if the part later sees temperatures within PEEK's crystallization range. Higher crystallinity directly increases this delayed shrinkage.

Crystallinity and cooling rate

Higher mold temperature and slower, more uniform cooling increase crystallinity and therefore both molding and post-mold shrinkage, while rapid quenching suppresses crystallinity but can sacrifice long-term dimensional stability.

Fillers and flow direction

Fiber or mineral fillers (glass, carbon) significantly reduce overall shrinkage and anisotropy. Unfilled PEEK often shows about 1.2–1.5% shrinkage in the flow direction and 1.4–1.9% transverse to flow, so gate location and fiber orientation must be carefully managed to prevent warpage.

Mold temperature

Keep PEEK molds hot, typically around 150–200 °C, to ensure proper crystallization while balancing cycle time. Maintaining a stable mold temperature is critical for consistent shrinkage and dimensional accuracy.

Packing and cooling

Use sufficient holding pressure and holding time to compensate for volumetric shrinkage during solidification. The cooling system should be designed for uniform temperature distribution so that shrinkage and post-shrinkage do not vary across the part.

Design relatively uniform wall thickness and avoid abrupt section transitions so that cooling and crystallization proceed evenly and local shrinkage gradients are minimized.

When extremely tight tolerances are required, consult the specific PEEK grade's shrinkage data, oversize the cavity according to flow and cross-flow values, and validate with dimensional studies that include both immediate and aged measurements to fully capture post-shrinkage behavior.