Polyether ether ketone (PEEK) is a high-performance, semi-crystalline engineering thermoplastic known for its outstanding mechanical strength, chemical resistance, and thermal stability. Among all its thermal characteristics, the melting point is one of the most important because it defines the processing window and determines where PEEK can be safely used in high-temperature environments.

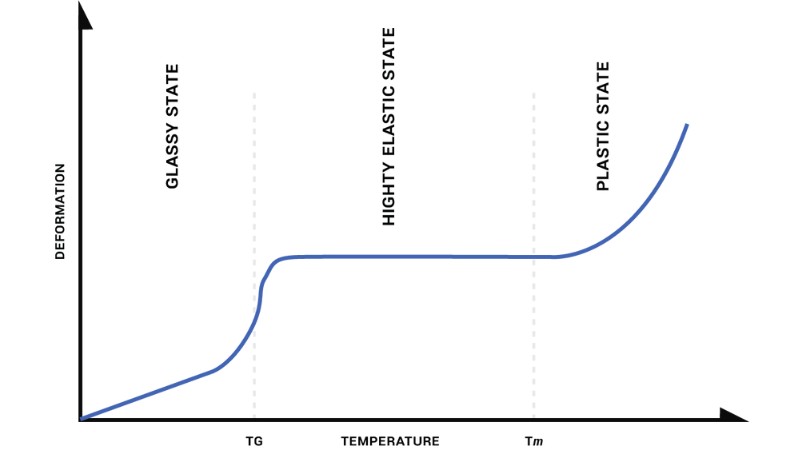

Unlike amorphous plastics, PEEK contains both amorphous and crystalline regions. Its melting point (Tm) represents the temperature at which the crystalline regions melt. This is different from the glass transition temperature (Tg), the point at which the amorphous regions transition from hard to rubbery.

Understanding both temperatures is essential for selecting PEEK for high-heat applications and choosing the right processing method.

Most PEEK materials exhibit a melting point of approximately 340–343°C (644–649°F).

Different manufacturers may list slightly different values, but they all fall within this narrow, high-temperature range.

This exceptionally high melting point is one of the main reasons PEEK is used in aerospace, automotive, oil & gas, medical devices, and semiconductor manufacturing.

Small variations in the reported melting point occur due to:

Grade differences (unfilled vs. carbon-fiber-filled vs. glass-fiber-filled)

Differences in crystallinity

Thermal history during testing

Testing method and heating rate

Annealing or quenching prior to measurement

Although these factors shift the thermal curve slightly, the melting point consistently stays around the 340–343°C range.

Because PEEK melts at such a high temperature, molding and extrusion require specialized equipment:

Melt temperature: Typically 360–400°C depending on grade and product geometry

Barrel and nozzle temperatures: Must be precisely controlled above the melting point

Mold temperature: Often set between 150–200°C to achieve proper crystallinity

Drying: Proper pre-drying prevents hydrolytic degradation during melt processing

Accurate temperature control is essential to avoid incomplete melting, poor flow, voids, and thermal degradation.

PEEK is commonly reinforced with fillers such as:

30% carbon fiber (CF30)

30% glass fiber (GF30)

Lubricating additives (PTFE, graphite)

While fillers generally do not drastically change the melting point, they affect other thermal behaviors:

Crystallization temperature

Cooling rate

Heat transfer

Dimensional stability

Mechanical performance at high temperature

Composite PEEK grades may require slightly adjusted processing conditions.

Differential Scanning Calorimetry (DSC) is used to measure:

Melting point

Crystallinity

Enthalpy of fusion

Effects of thermal history

Recrystallization behavior

A typical DSC curve for PEEK shows a sharp endothermic melting peak near 340°C.

Engineers should always report heating rate, sample preparation, and whether data comes from the first or second heating.

Although PEEK melts at around 343°C, its continuous service temperature is lower:

Commonly rated around 250–260°C for long-term use

Short-term or intermittent exposure may reach higher temperatures

This distinction is important:

Melting point controls processing; service temperature controls real-world durability.

Because of its high melting point, 3D printing PEEK requires:

Extruder temperatures around 380–420°C

Heated build chamber (~90–120°C)

Heated print bed (~130–160°C)

Incorrect thermal management leads to warping, weak interlayer bonding, and reduced mechanical properties.

During processing, PEEK can degrade if:

Melt temperature is too high

Residence time in the barrel is too long

Oxygen exposure at high temperature is excessive

The material is not properly dried

Proper processing conditions ensure color stability, mechanical strength, and long service life.

PEEK’s melting point of about 340–343°C is one of the primary reasons it is considered a top-tier ultra-high-performance thermoplastic. This high melting point provides outstanding heat resistance, but also demands specialized equipment and strict temperature control during processing.

Understanding melting point, crystallinity, and the differences between Tm and Tg helps engineers design more reliable components across demanding industries such as aerospace, automotive, medical, semiconductor, and energy.