In the world of high-performance engineering plastics, Polyether Ether Ketone (PEEK) stands in a league of its own. For designers and engineers pushing the boundaries in aerospace, medical, semiconductor, and automotive applications, PEEK machined parts are often the critical component that ensures success. But what makes machining this superstar polymer so unique, and how can you ensure your project leverages its full potential? Let's dive in.

Before we discuss machining PEEK, it's essential to understand why we go through the trouble. PEEK isn't your standard plastic. It's a high-performance thermoplastic with an exceptional combination of properties:

Extreme Thermal Resistance: Continuous service up to 480°F (250°C).

Outstanding Mechanical Strength: Retains stiffness and load-bearing capacity at high temperatures.

Inherently Chemical Resistant: Withstands harsh solvents and acids.

Excellent Wear & Abrasion Resistance: Ideal for bearings, seals, and dynamic parts.

Biocompatibility: Certified grades (like PEEK -OPTIMA) are suitable for long-term implantable devices.

Inherent Flame Resistance & Low Smoke Emission: Crucial for aerospace and mass transit.

These properties make it a perfect metal replacement for weight reduction, corrosion avoidance, or where electrical insulation is needed.

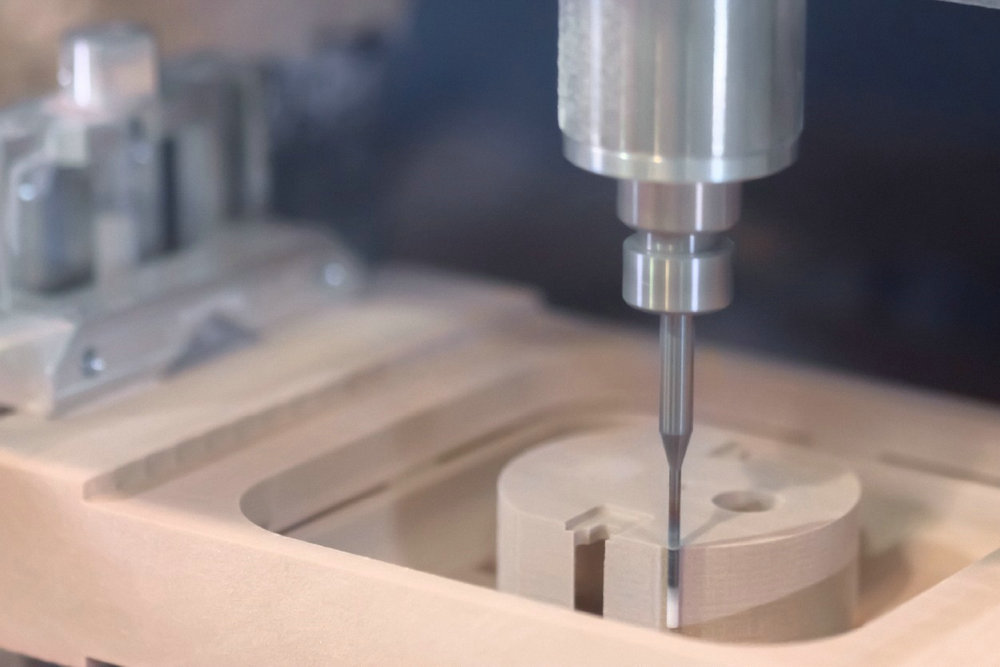

While PEEK is available in injection-molded forms, many low-volume, high-precision, or prototype components are best created through CNC machining. Machining PEEK plastic requires a specific approach to achieve the flawless results the material is capable of.

Key Challenges in Machining PEEK:

Heat Management: Despite its high-temperature rating, excessive localized heat from machining can soften the material, leading to gumminess, poor surface finish, and dimensional inaccuracy.

Internal Stresses: PEEK stock (rod, plate) can have residual stress from manufacturing. Improper machining techniques can cause parts to warp or distort as material is removed.

Abrasive Nature: Certain reinforced grades (e.g., carbon or glass-filled) are abrasive and can accelerate tool wear.

Expert Tips for Successful PEEK Machining:

Sharp Tools are Non-Negotiable: Use sharp, positive-rake carbide tools. High-speed steel tools will dull quickly.

Master the Coolant: Use a constant stream of compressed air or a mist coolant to dissipate heat. Avoid water-based coolants that can be absorbed by some PEEK grades.

Optimize Speeds and Feeds: Higher speeds with moderate feed rates often work better than slow speeds, which can generate more friction heat.

Secure, Lightweight Clamping: Use firm but gentle clamping to avoid distorting the workpiece. Consider custom jigs for complex parts.

Stress-Relief Strategy: For critical tolerance parts, machine in stages, allowing the material to stabilize between operations.

The process for creating precision PEEK machined parts typically follows these steps:

Material Selection: Choosing the right grade (virgin, glass-filled, carbon-filled, bearing-grade with PTFE) is the first critical decision.

Stock Preparation: Sourcing stress-relieved or annealed stock material can prevent future warping.

CNC Programming: Software programming that optimizes tool paths for heat dissipation and minimizes abrupt directional changes.

Precision Machining: Executed on state-of-the-art 3, 4, or 5-axis CNC mills and lathes by experienced machinists.

Deburring & Finishing: Using specialized techniques to achieve the required surface finish (Ra value) without damaging delicate features.

QA & Inspection: Final verification using CMMs (Coordinate Measuring Machines) and micrometers to ensure every dimension meets the stringent drawing specifications.

For many, outsourcing to a specialist is the most efficient path. Look for a machine shop that:

Has Explicit PEEK Experience: Ask for case studies or sample parts.

Understands Your Industry Needs: Medical (cleanroom capability), aerospace (documentation), etc.

Emphasizes Process Control: They should be able to explain their approach to heat and stress management.

Provides Design for Manufacturability (DFM) Feedback: A good partner will help optimize your design for machining success.

Machining PEEK is not just about cutting plastic; it's about meticulously crafting a high-performance engineering material into a reliable component. By understanding the material's behavior and respecting the machining process, you unlock a world of design possibilities where strength, lightness, and resistance converge. Whether you're designing a spinal implant, a drone component, or a wafer handling robot arm, precision PEEK machined parts can be the silent, robust workhorse that ensures your innovation performs flawlessly.