Discover PEEK Polymer - a high-performance material with outstanding strength, chemical resistance, and thermal stability. Learn about PEEK polymer uses, properties, structure, and the PEEK polymer formula. Available in various shapes (rod, sheet, pipe), with a density of 1.30 g/cm³ and a price range of $40-70 USD/kg. Trusted PEEK polymer manufacturers offer reliable, high-quality solutions for your projects.

_______________________________________________________________________________________________________________________________________________________________________

PEEK Polymer (Polyether Ether Ketone) is a premium thermoplastic known for its superior mechanical properties, exceptional chemical resistance, and thermal stability. Its unique characteristics make it a top choice for industries that require high-performance materials, such as aerospace, automotive, medical, and industrial manufacturing.

PEEK Polymer Properties

High Strength and Durability: PEEK polymer provides excellent mechanical strength, ensuring long-lasting performance even in high-stress conditions.

Thermal Stability: PEEK polymer can withstand temperatures up to 250°C without compromising performance, making it suitable for demanding thermal environments.

Chemical Resistance: With resistance to a wide range of chemicals, oils, and solvents, PEEK polymer is ideal for harsh environments.

Low Friction and Wear Resistance: The low friction properties of PEEK polymer make it ideal for bearings, seals, and other moving components that endure constant friction.

PEEK Polymer Formula

The PEEK polymer formula is based on a polyaromatic ether ketone structure, offering a robust backbone that ensures both strength and chemical resistance. The formula is represented as:

C19H12O3

This chemical composition makes PEEK polymer a versatile material that can be used across various industries where high performance and longevity are required.

PEEK Polymer Structure

The PEEK polymer structure consists of a rigid, crystalline thermoplastic material with a highly aromatic backbone. The polymer structure enables PEEK polymer to exhibit outstanding strength, stiffness, and high thermal resistance. The repeating ether and ketone groups within its molecular structure provide exceptional resistance to harsh chemicals, high temperatures, and wear, making it suitable for challenging engineering applications.

PEEK Polymer Density

The density of PEEK polymer is 1.30 g/cm³, which contributes to its strength while maintaining a relatively lightweight form. This density ensures that PEEK polymer retains its structural integrity while being easy to handle for manufacturing and assembly processes.

PEEK Polymer Uses

PEEK polymer is used in a wide range of applications where durability, high temperature resistance, and chemical resistance are essential:

Medical Devices: PEEK is commonly used in spinal implants, dental devices, and surgical instruments due to its biocompatibility.

Aerospace and Automotive: PEEK is used in engine components, seals, and various critical parts that need to withstand high stress and extreme conditions.

Industrial Manufacturing: PEEK polymer is ideal for bearings, gaskets, seals, and electrical insulations due to its excellent wear resistance and mechanical strength.

PEEK Polymer Price

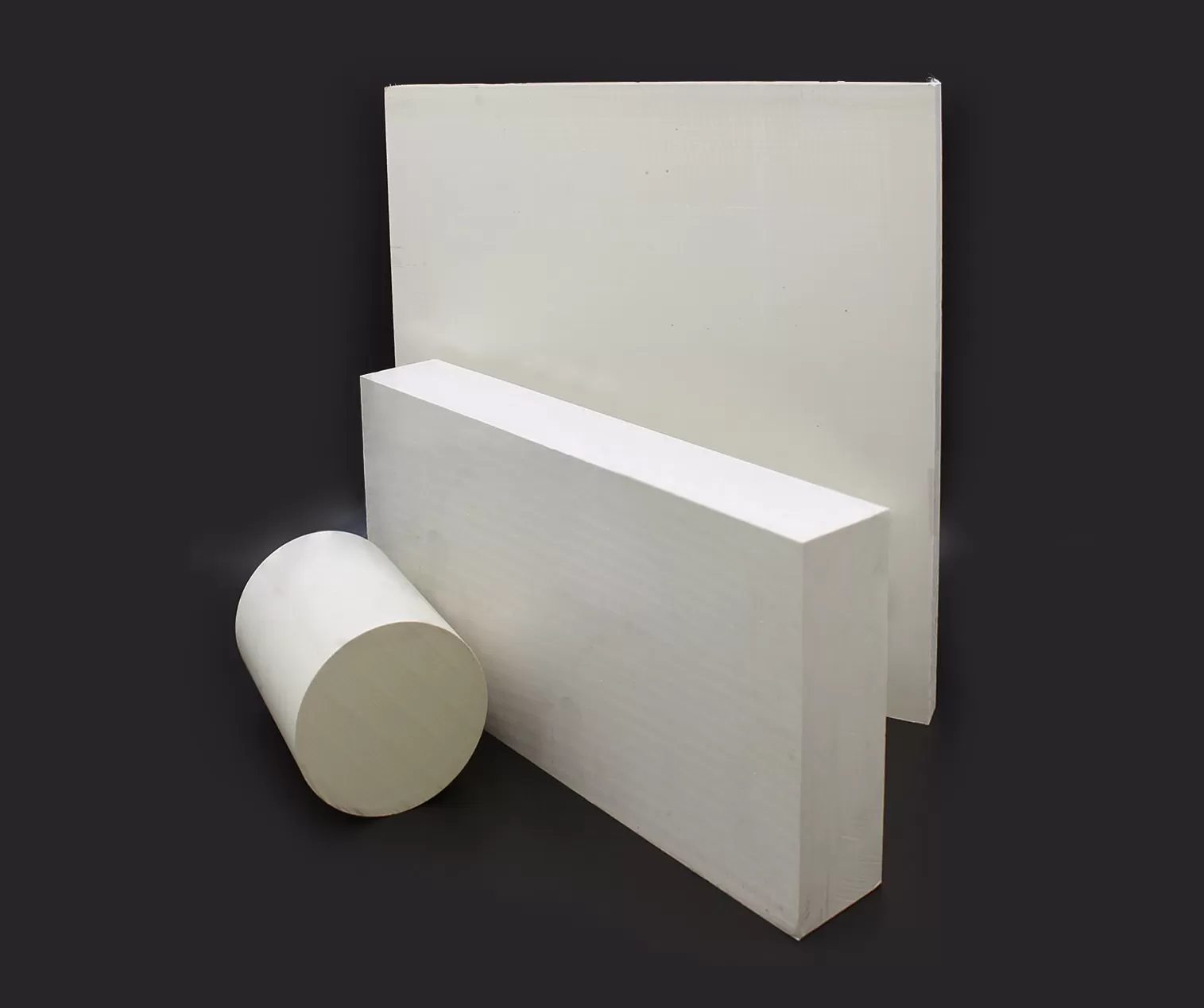

We offer PEEK polymer for sale in different forms such as pellets, rods, sheets, and pipes. Our PEEK polymer price ranges from $40-70 USD/kg, varying depending on whether you purchase pellets or shaped materials like rod, sheet, or pipe. The pricing is tailored to your specific order size and form, offering flexibility to meet your project’s needs. Additionally, PEEK polymer price is competitive and designed to provide the best value for high-performance materials.

As PEEK polymer manufacturers, we are committed to providing high-quality material solutions tailored to your specific project needs. We offer a broad selection of PEEK polymer uses to fit various industries and applications. Our goal is to help you solve complex engineering challenges with durable, reliable materials.

Explore our range of PEEK polymer products today and take advantage of our competitive pricing and excellent customer support. Whether you are looking for high-performance solutions for mechanical applications or need a versatile material for medical devices, we have the right product for you.

_______________________________________________________________________________________________________________________________________________________________________

PEEK Polymer Composition

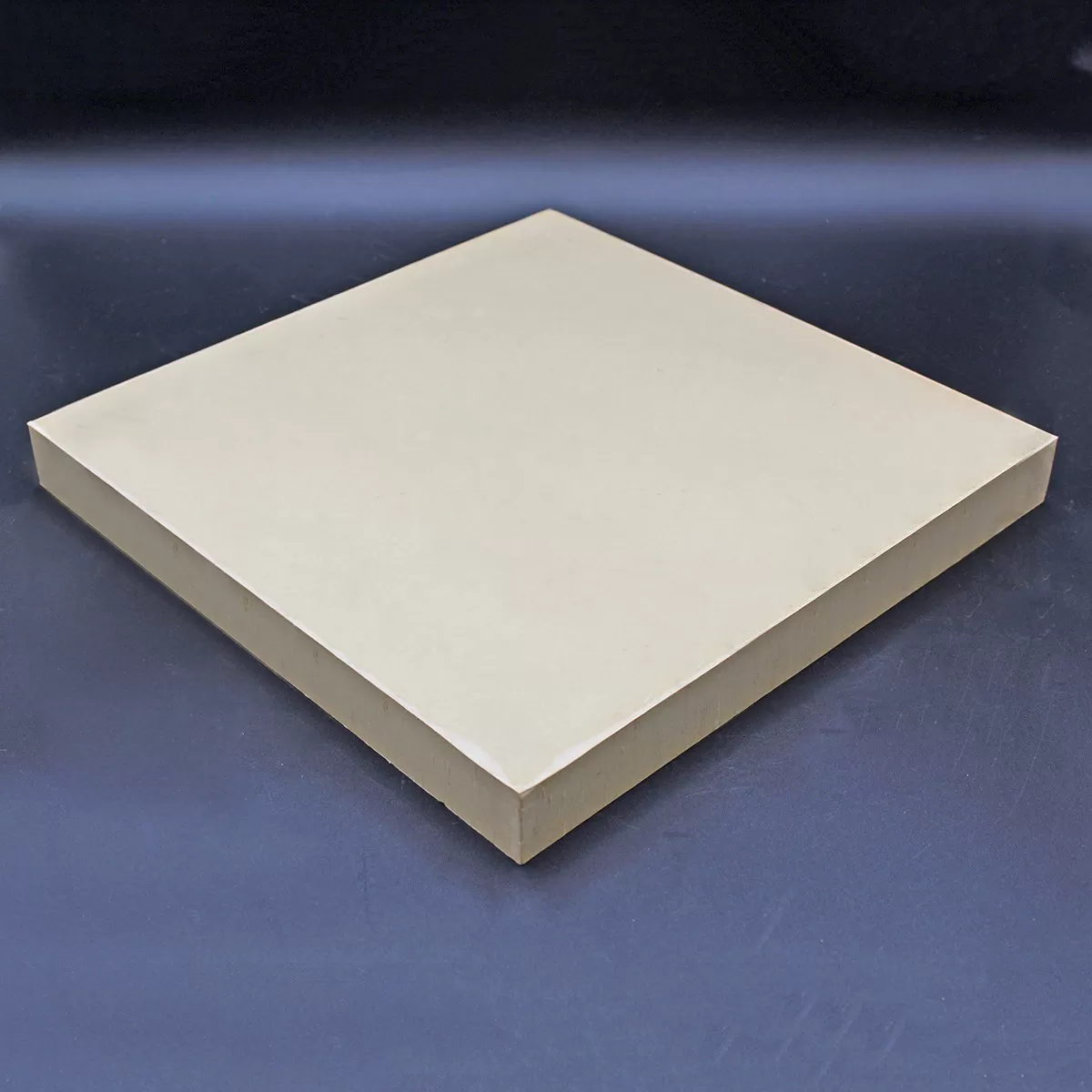

ARKPEEK-1000: 100% PEEK

Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types.

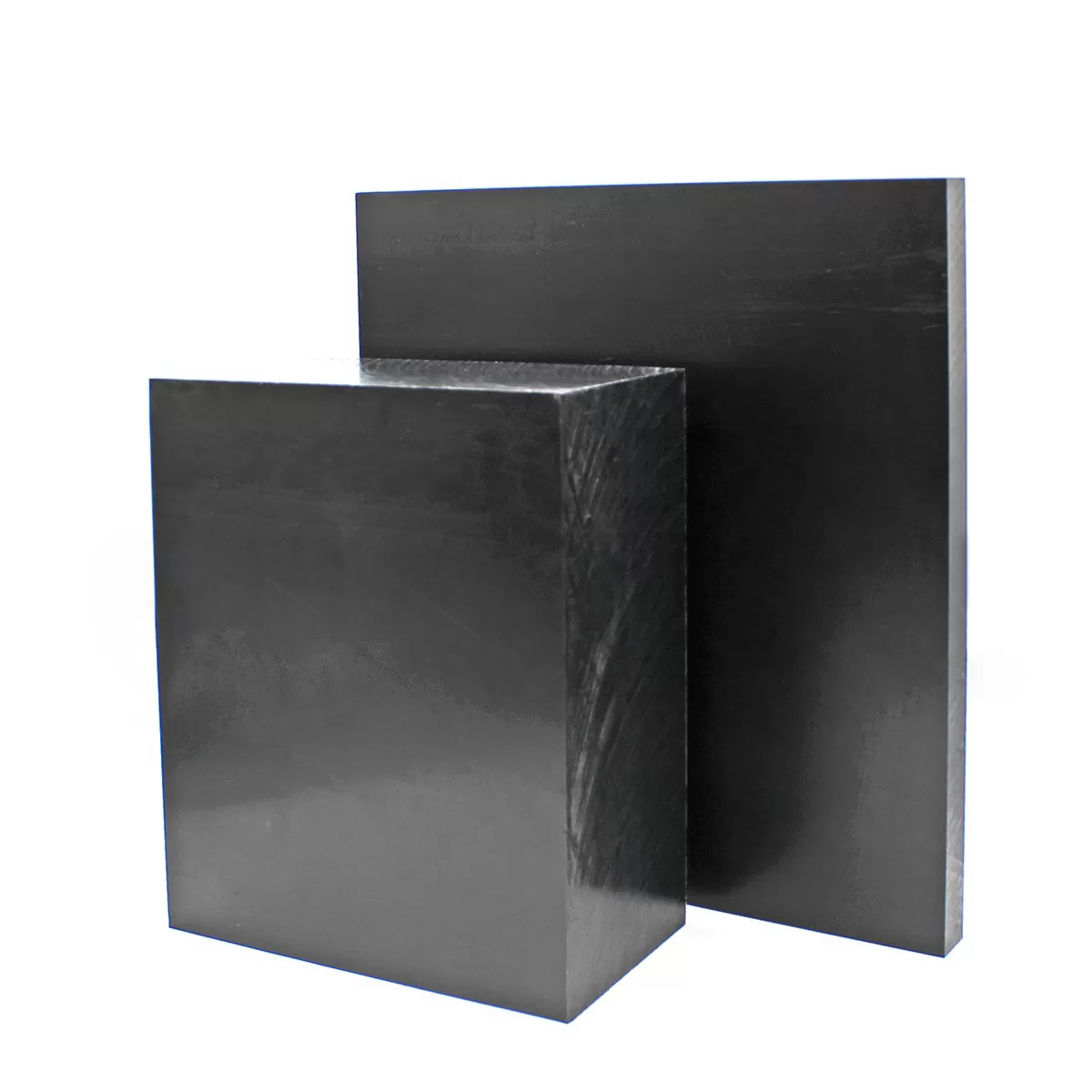

ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK

Carbon fibre reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values.

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK

Glass filled PEEK exhibits increased mechanical strength and high rigidity. improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

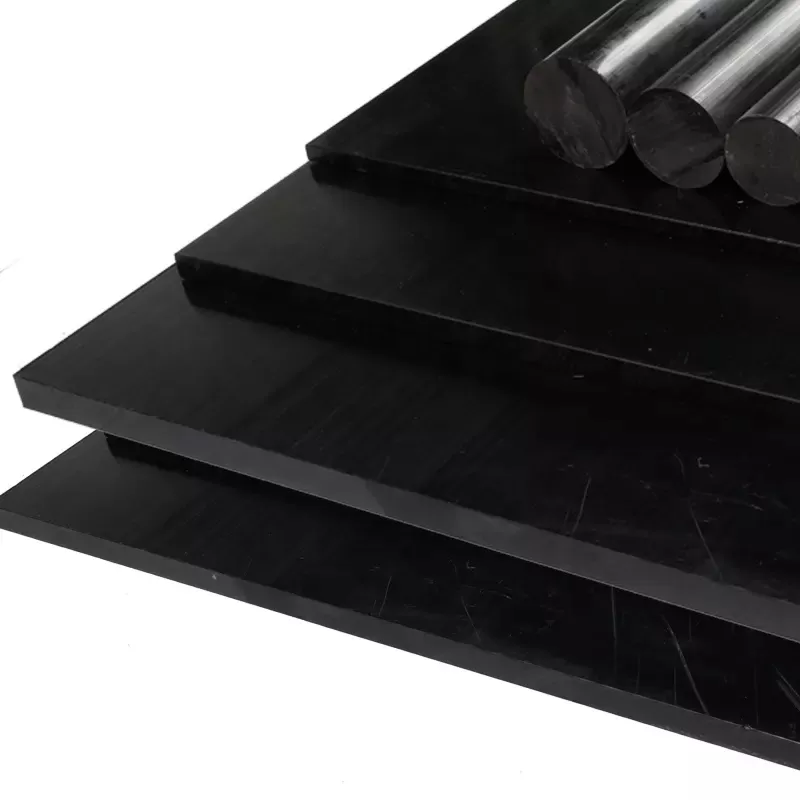

ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite + 70%

high performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical strength and high dimensional stability. The long term service temperature range of PEEK Rod is from -30°C to 250°C and has a short term maximum service temperature of 310°C.