A single statement from Tesla about their humanoid robot has made carbon fiber and PEEK materials a hot topic. Industry experts believe that carbon fiber reinforced polyether ether ketone (PEEK) high-performance thermoplastic composite materials will be the core materials for future humanoid robots.

Additionally, CF PEEK composite materials have been the focus of research in recent years. If breakthroughs are made in this type of composite material, it is expected to play a significant role in cutting-edge medical fields, particularly bringing new hope in orthopedic implants.

Advantages of CF/PEEK composite materials

Compared with traditional aluminum alloys and stainless steel, the density of aluminum alloy is 2.8g/cm3, stainless steel is 7.3g/cm3, and the density of continuous PEEK CF composite material is 1.51g/cm³. It is lightweight but has high strength, and some properties of CF-PEEK have surpassed stainless steel. Additionally, continuous carbon fiber reinforced PEEK has good X-ray translucency, making clinical surgeries more intuitive and safe. Carbon fiber reinforced materials do not have the cold feeling of metal, making surgeons feel more comfortable during surgery.

Compared with traditional carbon fiber powder-modified materials, the high strength and modulus characteristics of carbon fiber give PEEK-CF composite materials high strength, high elastic modulus, and deformation resistance. Mechanical strength is increased by at least three times, modulus is also increased by at least three times, with better dimensional stability and deformation resistance.

With such high-quality composite materials, which companies are currently involved?

Currently, CF/PEEK production technology is only mastered by a few companies such as Japan's Toray, Netherlands' TenCate (acquired by Toray), UK's Victrex, ARKPEEK, etc., mainly used in aerospace and other cutting-edge fields, with significant strategic significance and broad market space. The research and development of CF/PEEK in China are mainly concentrated in universities, research institutes, and a few enterprises. Apart from the following two companies, industrial production has not yet been realized.

Currently, only two companies in China can mass-produce high-quality PEEK composite materials

1, ZYPEEK

ZYPEEK was established in December 2006, focusing on the research, production, and sales of polyether ether ketone (PEEK), with its main products being resin-based PEEK. It has formed the existing product system of "two categories, three brands, six series" with a total of 52 specifications. The company's current production capacity is 1000 tons of PEEK per year. In September 2023, Jilin China Research High Polymer Materials Co., Ltd. (China Research Co., Ltd.) applied for IPO on the Sci-Tech Innovation Board.

It is reported that in this IPO, China Research Co., Ltd. plans to raise 455 million yuan for the comprehensive factory project (Phase II) of the annual production of 5000 tons of polyether ether ketone (PEEK) deep processing series products, innovation and technology research and development center project, Shanghai carbon fiber polyether ether ketone composite material research and development center project, and supplementary working capital project.

2, PEEKChina

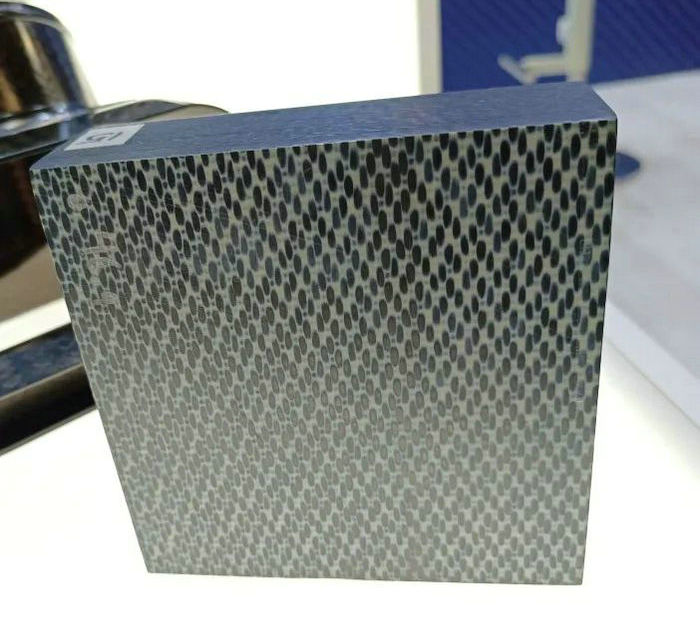

PEEKChina, Intl's brand known as ARKPEEK, focuses on the application research, production, and sales of high-performance special engineering plastic resins and profiles such as PEEK, forming a complete industrial chain with PEEK raw material resin polymerization, modified granulation, continuous extrusion molding of plates, rods, pipes, and injection molding and machining of finished parts. With technical support from Jilin University and Donghua University, ARKPEEK is committed to the application research, production, and sales of continuous carbon fiber CF/PEEK thermoplastic composite materials. The company has developed special resins for PEEK composite materials-ARKPEEK-CF30® and ARKPEEK-MOD® using its own polymerization device and processed carbon fiber with independently innovative high-temperature sizing agents to produce CF/PEEK thermoplastic composite materials with excellent comprehensive performance.

Now let's take a look at which international companies are also producing such products.

1, EVONIK

Evonik, originating from Germany, is an innovative industrial group mainly dedicated to developing three high-yield and promising industries: chemicals, energy, and real estate. Evonik Industrial Group has been producing specialty chemicals in China since the early 1990s and has established extensive trade relations with China even earlier. Today, Evonik has more than 20 companies in China, with production bases in dozens of cities across China. Evonik products are of excellent quality and diverse, serving customers in China and around the world.

2, Solvay

Solvay is a multinational chemical group headquartered in Brussels, the capital of Belgium, founded by Belgian chemist Ernest Solvay in 1863. Solvay Group's products are widely used in various industries, with 90% of its sales products ranking among the top three in the world.

3, Victrex

In 1978, Imperial Chemical Industries (ICI) of the UK first developed PEEK. Only three years later, the first batch of commercialized PEEK polymers "VICTREX PEEK" series (including glass and carbon filled products) was launched. In 1993, Victrex acquired ICI's PEEK business and began independent operation. The VICTREX® PEEKTM series resins developed by Victrex have become the industry benchmark. This series of resins covers nine categories and forty-nine varieties, including pure resin, composite reinforced resin, and deeply purified granules. In addition, Victrex has developed various PEEK products, such as coating special materials VICTREX® VICOTETM series and PEEK film VICTREX® APTIVTM series, etc., with significant advantages in vertical integration of the industrial chain.

4, Toray

Toray, Japan, as the leader in the global PAN-based carbon fiber field, not only has a series of mature high-performance carbon fibers, but also has established a complete carbon fiber composite material database system. Its carbon fiber reinforced PEEK composite materials mainly include two products, Toray Cetex® TC1200 and Toray Cetex® TC1220. Toray Cetex®TC1200 is a high-end carbon fiber reinforced thermoplastic composite material, which uses semi-crystalline thermoplastic PEEK as the matrix and has excellent mechanical properties.

5, TEIJIN

Teijin Corporation reported on April 12, 2023, that its carbon fiber reinforced and polyether ether ketone (PEEK) based materials Tenax thermoplastic woven fabrics (TPWF) and Tenax thermoplastic composite laminates (TPCL) have been certified by NCAMP (National Center for Advanced Materials Performance) in Wichita, Kansas, USA. This qualification makes carbon fiber/PEEK fabrics and reinforced laminated materials technology available to a wider range of original equipment manufacturers, first-tier, and second-tier suppliers. Manufacturers can use the public NCAMP database to demonstrate equivalency and obtain FAA certification at lower costs than qualified materials themselves.

6, Icotec AG

https://www.icotec-medical.com/

Icotec AG was founded in 1999 and is a family-owned small to medium-sized enterprise based in Altstätten, Switzerland. Icotec has developed, manufactured, and sold non-metallic spinal implants made from BlackArmor®. Icotec's proprietary BlackArmor® material is composed of continuous carbon fibers combined with polyether ether ketone (PEEK), using icotec's unique composite material flow molding (CFM) injection molding technology. The non-metallic BlackArmor@Carbon/PEEK prepared by it has X-ray transparency and characteristics similar to natural bone -- two basic features optimized for postoperative treatment of patients.

7, TenCate

Dutch TenCate has always been a major supporter and developer of continuous fiber reinforced thermoplastic composite materials. The company has launched a series of materials to the market, including carbon fiber, glass fiber, and aramid fiber reinforced PEEK, PEI, and PPS resin unidirectional fiber prepreg, sold under the TenCate Cetex® brand. In 2018, TenCate Advanced Composites Holdings (TACHD) was acquired by Toray Group of Japan. The TenCate Cetex® TC1200 product uses standard or medium modulus carbon fibers or S-2 glass fibers. The void content of TenCate Cetex TC1200 is very low (<1%). The provided typical carbon single board width is the standard 6-inch (75mm) width, and an optional 12-inch (305mm) width is also available. Narrow slit widths for ATL processing can be obtained through secondary longitudinal cutting.