PEEK (Polyether Ether Ketone) is an aromatic, semi-crystalline thermoplastic polymer known for its exceptional combination of mechanical strength, heat resistance, and chemical stability. Its molecular structure - composed of aromatic rings, ether, and ketone linkages - provides excellent thermal and chemical resistance. Owing to these properties, PEEK is widely used in aerospace, medical devices, and automotive engineering.

Processing quality is closely tied to the material’s intrinsic characteristics. To ensure optimal performance, manufacturing parameters must be carefully matched to each forming technique.

PEEK processing methods include compression molding, extrusion, injection molding, hot pressing, and 3D printing.

Process Overview:

PEEK raw material is dried at 150–200°C for 6–8 hours, then filled into a precision-machined, heat-conductive mold coated with a release agent. The material is pressed at 350°C and 7–14 MPa for around 10 minutes, slowly cooled to room temperature, demolded, and annealed for stress relief.

Compression molding is suitable for medium-sized structural parts such as aerospace brackets and medical prosthetic bases.

Common Issues and Solutions:

1, Vacuum Voids:

Caused by insufficient pressure or incomplete air evacuation. Optimize molding pressure and ensure proper venting during powder compression and melting.

2, Surface Contamination:

Results from unclean molds or powder contamination. Clean molds and check drying ovens and raw materials.

3, Dark Color or Material Degradation:

Caused by overheating or prolonged high-temperature cycles. Check temperature settings and heating duration.

4, Unmelted Powder:

Indicates underheating or insufficient dwell time at high temperature. Verify that the melting zone temperature and time are adequate.

Process Overview:

PEEK pellets are dried at 120–150°C for 4–6 hours, preheated in segments from 300–390°C, melted at low screw speed, extruded through a die, then cooled by air or water, and stress-relieved by annealing.

This method is ideal for continuous production of tubes, rods, and sheets (e.g., high-temperature tubing and electronic insulation plates).

Common Issues and Solutions:

1, No Feeding:

Hopper blockage: Caused by failed cooling or material bridging. Clear the hopper and inspect cooling water circuits.

Screw feeding failure: Check for material build-up or excessive feed zone temperature.

2, High Extruder Torque: Caused by high melt viscosity. Increase barrel temperature or shear rate. Keep melt temperature above 365°C.

3, Surface Defects or Moisture Marks: Due to insufficient drying. Ensure proper drying temperature and cycle.

4, Cracks in Tubes or Rods: Caused by internal stress. Optimize by reducing extrusion speed or increasing coolant temperature.

5, Low Crystallinity: Adjust cooling media temperature according to product thickness for uniform crystallization.

Process Overview:

PEEK pellets are dried at 120–150°C for 4–6 hours, then heated to 360–400°C, with mold temperature at 150–180°C. The molten resin is injected under high pressure, cooled, demolded, and annealed at 150–200°C to remove residual stress.

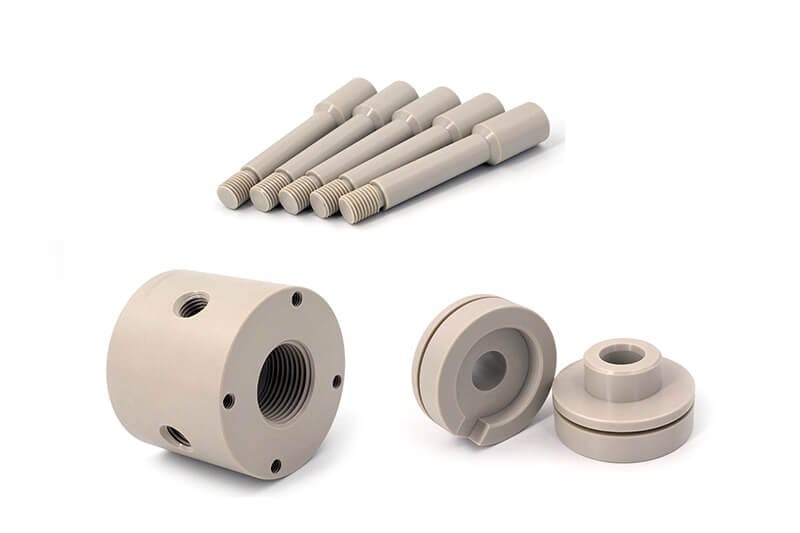

This process suits mass production of complex parts such as micro gears and medical connectors.

Common Issues and Solutions:

1, Uneven Color or Transparency: Caused by inconsistent crystallinity. Improve by raising mold temperature and ensuring uniform heat distribution.

2, Delamination: Occurs in thin-walled sections due to excessive shear. Adjust gate position or part wall thickness.

3, Burn Marks: Result from trapped air heating up. Lower injection speed or optimize venting design.

4, Black Spots: Caused by material contamination or carbonization. Inspect feed materials and equipment cleanliness.

5, Color Difference or Stress Whitening: Often due to excessive holding pressure or poor ejection design. Modify mold or process parameters.

6, Flow Lines ("Snakeskin" Pattern): Caused by high flow speed and poor cavity design. Lower injection speed or improve mold geometry.

7, Cold Slugs: From solidified material in the nozzle. Increase nozzle temperature or add a cold slug well.

8, Air Traps: Due to fast injection or plasticizing speed. Lower these rates and adjust backpressure.

9, Sink Marks or Voids: Caused by insufficient packing in thick sections. Increase holding pressure/time and optimize flow path.

10, Wavy Surface: Results from low injection rate or excessive pressure loss. Increase melt/mold temperature and injection speed.

11, Moisture Streaks: Thin surface lines due to poor drying. Ensure full material dehydration.

12, Fiber Floating: Seen in fiber-reinforced grades. Increase melt/mold temperature or injection speed.

13, Tiger Stripes: Alternating glossy/matte lines from pulsating flow. Increase melt/mold temperature or gate size.

14, Short Shots (Incomplete Filling): Caused by poor flow. Increase melt/mold temperature, injection speed, or gate number.

15, Warping and Deformation: Results from uneven shrinkage or crystallinity. Adjust mold temperature balance, packing time, and cooling.

Proper control of temperature, pressure, and drying parameters is key to achieving high-quality PEEK parts. Whether molding, extruding, or injecting, understanding defect causes allows engineers to optimize processing and fully unlock PEEK's superior performance.