In the field of engineering plastics, PEEK (Polyether Ether Ketone) is a representative high-performance thermoplastic. Known for its outstanding heat resistance, wear resistance, chemical stability, and excellent dimensional stability, PEEK has become a preferred material in semiconductor component manufacturing and other precision applications.

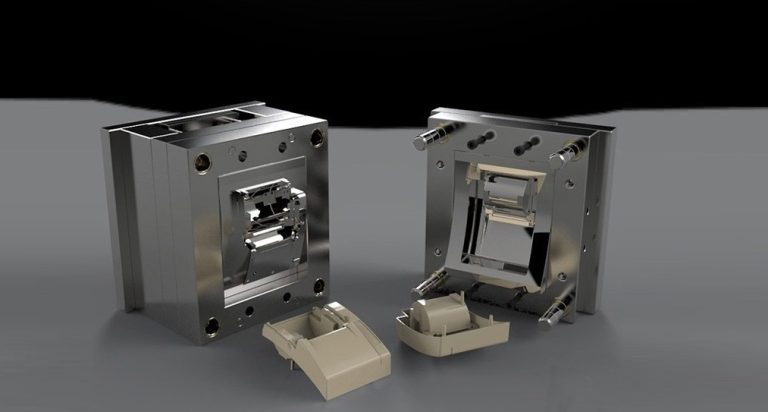

For engineers, whether PEEK can be reliably molded through injection molding is crucial in determining its practical applications. In practice, PEEK injection molding can fully meet the requirements of high-end industries - as long as every step of the process is carefully controlled.

PEEK is a semi-crystalline thermoplastic polymer with a high melting point and a relatively narrow processing window. Compared to conventional engineering plastics, PEEK is more sensitive to temperature and moisture.

If the raw material is not properly dried, defects such as bubbles, silver streaks, or weld lines may appear during molding, directly affecting appearance and mechanical strength.

Therefore, the first and most critical step in PEEK injection molding is strict material drying, ensuring the moisture content is reduced to an acceptable level before processing.

Temperature control is key during the melt plasticization phase. PEEK must be processed at temperatures above 350 °C to achieve proper melt flow, but excessive temperature can lead to molecular chain degradation, reducing toughness and durability.

Thus, injection molding machines must have precise temperature control systems to keep the melt temperature stable.

At the same time, mold temperature should also remain high to prevent premature solidification during filling. The coordination between melt and mold temperature directly affects mold filling, surface quality, and dimensional accuracy of the final product.

Both back pressure and injection speed play important roles in the molding process.

Too high back pressure increases shear heating, which can degrade the polymer.

Too low back pressure may cause poor melt homogeneity.

Proper back pressure ensures melt uniformity and reduces internal stress.

Similarly, injection speed must be optimized:

Too fast may cause shear degradation,

Too slow can lead to short shots or weld lines.

Achieving the right balance between speed and pressure ensures stable molding and consistent part quality.

Cooling and post-treatment significantly affect dimensional stability and wear resistance.

Rapid cooling can cause residual stress, leading to warpage or cracking. Controlled cooling helps minimize stress concentration and maintain product reliability.

For high-precision semiconductor components, annealing is often performed as an additional process. Under constant temperature conditions, annealing relieves residual stress, improving toughness and long-term stability.

The standardization of the PEEK molding and post-treatment process determines whether products can maintain stable performance under high-temperature and high-wear conditions.

Compared with machining, injection molding offers higher production efficiency and better material utilization.

Machining is suitable for small batches or complex parts but often results in material waste and longer production cycles.

PEEK injection molding, on the other hand, allows mass production with excellent consistency in a shorter time.

In semiconductor manufacturing, maintaining stable size and performance across batches is key to improving productivity and reducing costs.

Despite its advantages, PEEK injection molding does present some challenges - such as complex mold design, high equipment investment, and longer process tuning cycles.

However, the benefits in product performance, efficiency, and uniformity far outweigh these limitations.

Establishing a comprehensive quality traceability system is essential. Every stage - from raw material batches, process parameters, and inspection records to shipment data - should be systematically documented.

Regular testing of dimensions, mechanical properties, and thermal stability helps ensure reliability and continuous process optimization.

One notable strength of PEEK injection molding is its flexibility. By adjusting mold designs and processing parameters, manufacturers can quickly switch between different product specifications.

This adaptability is particularly valuable in the semiconductor industry, enabling fast response to diverse production needs and shorter delivery times.

PEEK is a premium thermoplastic material that can be stably molded through precise injection molding processes.

Through strict material drying, precise temperature control, optimized back pressure and injection speed, and well-managed cooling and annealing steps, manufacturers can ensure product reliability under high-temperature and high-wear conditions.

Compared with machining, PEEK injection molding offers superior efficiency, consistency, and scalability - making it an ideal choice for demanding industrial applications.

With continuous advances in process technology and equipment, PEEK molding will continue to expand its role across multiple high-performance fields.