On May 2, 2025, Polymer Composites published a study titled "Investigation on three-dimensional defect evolution and damage mechanisms of continuous carbon fiber reinforced PEEK composites under tensile loading." This research, conducted by the School of Electrical and Electronic Engineering of Huazhong University of Science and Technology, School of Mechanical Engineering of Xi’an Jiaotong University, and the High-Energy Beam Processing Lab of the China Academy of Aerospace Manufacturing Technology, explored how defects evolve and how damage occurs in continuous carbon fiber reinforced PEEK (CCF/PEEK) composites under tensile stress.

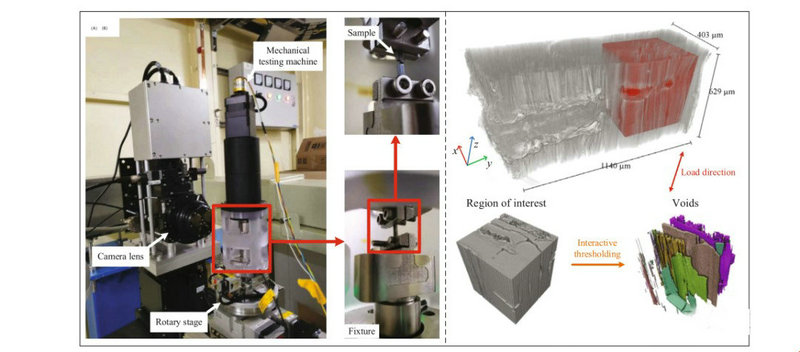

The study investigated 3D defect evolution and damage mechanisms in CCF/PEEK composites under tensile loading using Synchrotron Radiation X-ray Computed Tomography (SR-CT) and Digital Volume Correlation (DVC).

Key findings include:

Before failure, strain concentrated in areas with densely distributed fibers.

After failure, strain shifted to interlayer cracks.

Defect evolution analysis revealed that the coalescence and growth of defects around fibers may signal impending failure.

Weak interfacial bonding between fiber and resin was identified as the primary cause of tensile failure in CCF/PEEK composites.

These insights provide valuable information for failure prediction and optimization of forming processes.

A rectangular Region of Interest (ROI) sized 70×70×164 voxels was selected to track defect evolution during tensile loading. Defects were segmented into pores and cracks via grayscale thresholding and statistically analyzed. The number of pores decreased during tension, while cracks increased and aligned with the loading direction.

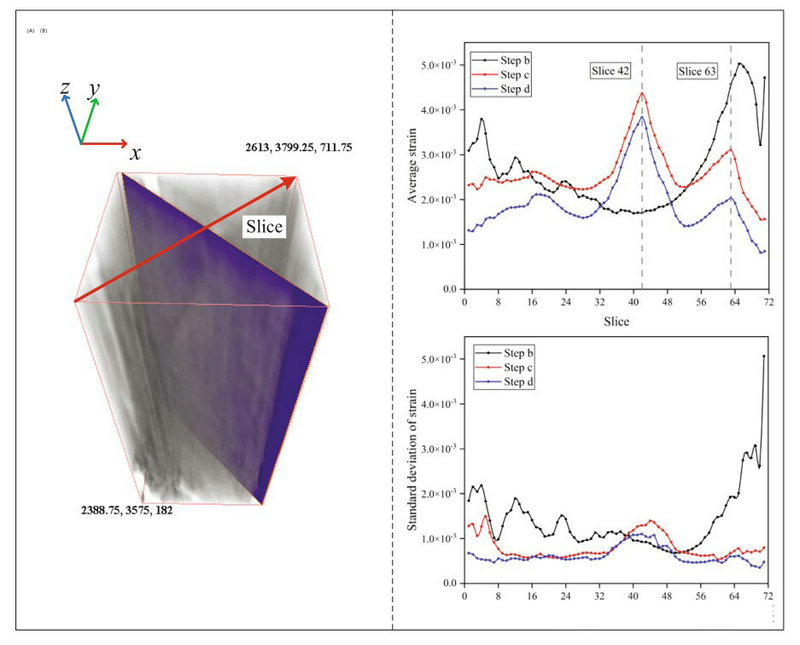

DVC analysis of strain fields revealed a redistribution during loading:

Pre-failure: Strain concentrated in fiber regions, indicating fiber fracture and debonding.

Post-failure: Strain concentrated in interlayer regions, indicating crack propagation.

These findings highlight how microstructures critically influence the macroscopic performance of CCF/PEEK composites.

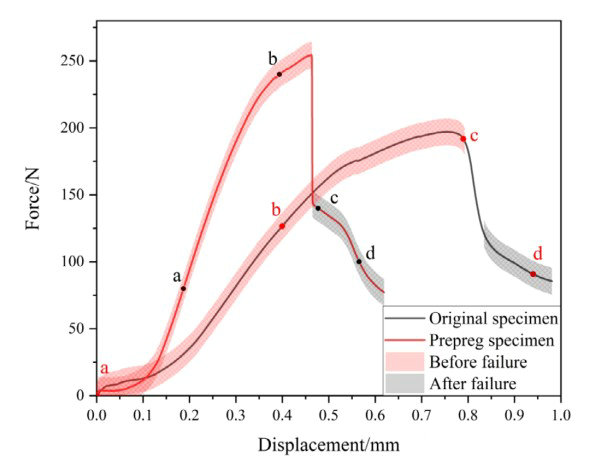

Samples were fabricated using 3D printing with continuous carbon fiber (CCF) and PEEK resin.

Two types were prepared:

Pre-impregnated samples

Raw samples

Both had ~15% fiber volume fraction.

High-speed X-ray imaging was conducted at the Shanghai Synchrotron Radiation Facility (SSRF). A custom semi-static tensile test machine applied uniaxial loading until sample fracture. Phase retrieval using the PAD-BA algorithm enhanced boundary contrast.

Force–displacement curves for both sample types were recorded. The initial loading stage showed linearity, confirming stable mechanical properties. The pre-impregnated sample showed prominent fiber breakage and mechanical failure during stage b–c.

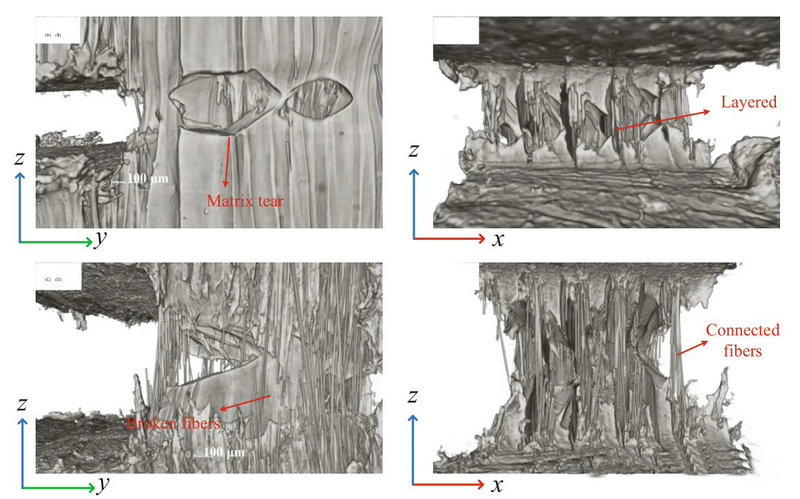

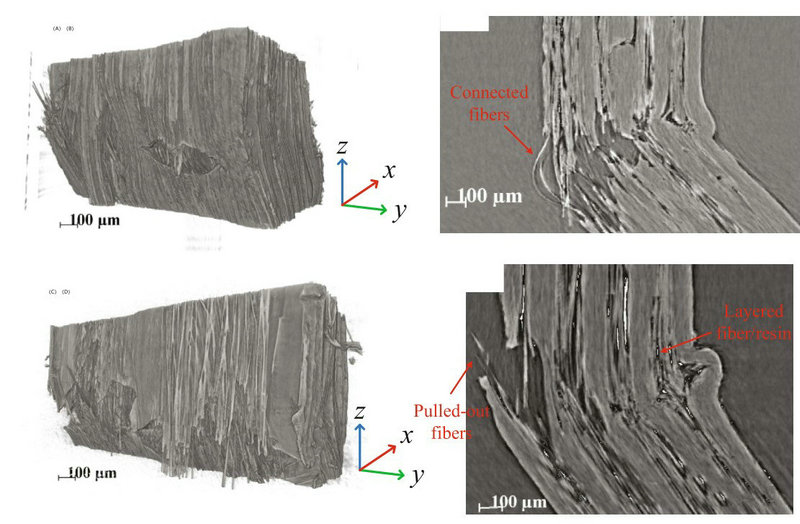

SR-μCT revealed internal microstructural changes during tensile loading. Matrix cracking was observed on the surface, with raw samples exhibiting more severe fracture. Interlayer cracks developed in pre-existing internal cracks, leading to delamination.

Internal voids were extracted and analyzed. Two major defect types were identified:

Cracks: Large, flat-volume voids.

Pores: Near-spherical, randomly distributed air gaps—likely from the printing process.

Finite Element Method (FEM)-based DVC revealed that strain concentration shifted from fiber zones to interlayer zones during failure progression, highlighting the redistribution of internal stress.

Two primary failure mechanisms were identified:

Fiber/resin interfacial failure

Matrix cracking

Defect evolution showed that fiber/resin interface degradation may precede final failure. DVC analysis effectively captured strain shifts, providing a basis for failure prediction and revealing key damage mechanisms in CCF/PEEK composites.