Materials science, as one of the core fields of modern technology, has evolved alongside human civilization and demonstrates remarkable vitality in today's technological revolution.Polymer materials, as a key component of modern materials science, have transitioned from traditional plastics to high-performance, lightweight, and intelligent materials.With the advancement of technology in China, the demand for high-performance polymer materials has increased. Among these, polyaryletherketones (PAEKs) have gained attention due to their excellent heat resistance and mechanical properties.

______________________________________________________________________________________________________________________________________

1. Polyether Ether Ketone (PEEK) Resin

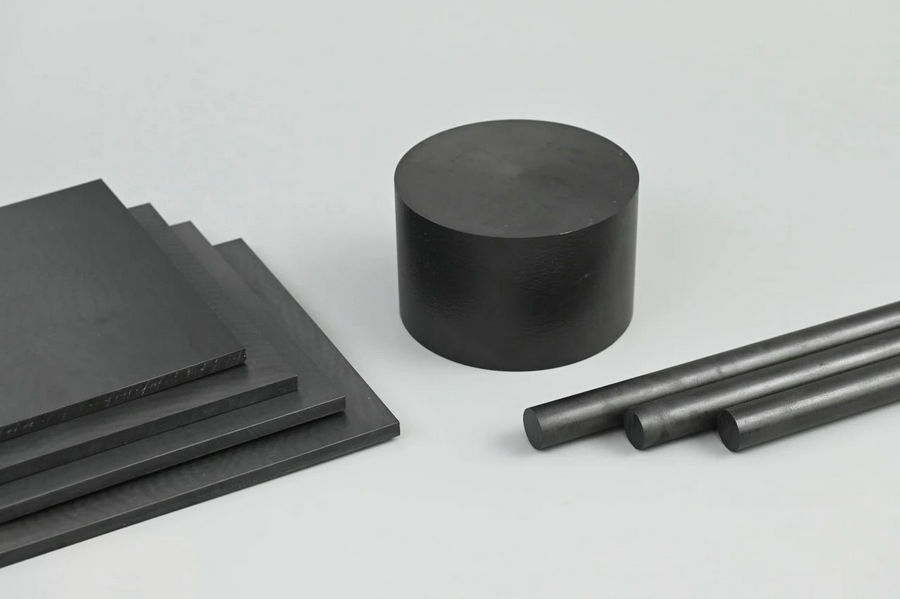

Polyether ether ketone (PEEK) is a semi-crystalline aromatic thermoplastic polymer and the most outstanding variety in the PAEK family. Its molecular chain consists of repeating ether (-O-) and ketone (-CO-) groups. PEEK exhibits exceptional wear resistance, resistance to acids, alkalis, organic solvents, and high temperatures, making it widely used in aerospace, medical devices, automotive industries, and more.

With industrial development, methods for composite processing and modification of PEEK have increased. The most common approach is fiber-reinforced PEEK.

Fiber-reinforced PEEK can be categorized into short fiber-reinforced PEEK, long fiber-reinforced PEEK, and continuous fiber-reinforced PEEK based on the form of the reinforcing phase. Due to its simplicity in molding and ease of processing, short fiber-reinforced PEEK is the most widely used. Common fibers for PEEK reinforcement include carbon fiber (CF) and glass fiber (GF).

______________________________________________________________________________________________________________________________________

2. Theoretical Mechanisms of Fiber-Reinforced PEEK

Academic research suggests the following key points:

Fibers inherently possess high modulus and strength, significantly enhancing the mechanical properties of composites.

Typically, PEEK has a tensile strength of about 100 MPa and an elastic modulus of 3.6 GPa. In contrast, carbon fiber (CF) exhibits a tensile strength ranging from 3500 to 6000 MPa and an elastic modulus between 230 and 600 GPa. Glass fiber (GF) has a tensile strength of 3100–3800 MPa and an elastic modulus of 72.5–75.5 GPa.

Since the tensile strength and elastic modulus of fibers far exceed those of the PEEK matrix, the composite's properties lie between those of the fiber and the matrix, thereby reinforcing PEEK.

2.1 Stress Transfer

Fibers enhance the composite's overall strength and modulus by transferring external loads through interfacial interactions with the matrix. Thus, strong adhesion between fibers and the PEEK matrix is critical for reinforcement. The strain rate sensitivity of interfacial strength significantly influences the composite's failure behavior.

Dr. Li Feiyang from ARKPEEK compared the tensile stress-strain curves of PEEK matrix and PEEK composites under dynamic and quasi-static loading at different strain rates.The study revealed that both composites showed improved tensile strength, with SCFR-PEEK exhibiting higher strength under all conditions, while SGFR-PEEK demonstrated greater tensile failure strain.

Carbon fibers provide higher stiffness, whereas glass fibers offer better toughness, leading to distinct performance differences in the two PEEK composites.

SEM analysis showed that pulled-out fibers were covered with PEEK matrix, creating a rough surface, indicating enhanced interfacial layers under dynamic loading.

Interfacial stress transfer efficiency is directly influenced by PEEK's transcrystalline structure on CF surfaces. Higher crystallinity and larger grain size promote stronger bonding between CF and PEEK.

2.2 Crystallization Effects

Fan Yeling from ARKPEEK investigated how fibers affect PEEK's interfacial crystallization, focusing on fiber properties and crystallization temperature.

Under high crystallization temperatures (250°C), PEEK formed spherulites up to 100 µm in radius. Crystalline fibers (e.g., CF) exhibited strong nucleation capabilities, forming transcrystalline layers.

At 200°C, PEEK still nucleated on fibers, but competing matrix crystallization prevented dense transcrystalline growth. At 150°C, matrix nucleation dominated, making transcrystalline layers indistinguishable. Crystalline fibers (e.g., CF) outperformed non-crystalline fibers (e.g., GF) in nucleation.

Untreated CFs poorly wet high-viscosity PEEK, creating micro-gaps at interfaces. These gaps weaken molecular interactions and mechanical friction, leading to interfacial failure under shear stress. Thus, fiber or matrix pretreatment is essential.

2.3 Interface Optimization

For CF, oxidation increases surface roughness and introduces oxygen-containing groups, forming hydrogen bonds with PEEK or sizing agents. This is particularly effective in graphene-reinforced PEEK systems.

For commercial CF/PEEK systems, selecting compatible sizing agents improves interfacial strength.

Wu Linggang studied interfacial shear strength in crystallinity-modified PEEK composites. Sized CFs showed tighter resin bonding and better wettability than unsized CFs, resulting in superior interfacial performance.

______________________________________________________________________________________________________________________________________

3. Conclusion

In summary, fibers significantly enhance PEEK's tensile strength and flexural modulus. However, interfacial effects must be carefully managed. Fiber-reinforced PEEK systems hold great potential for further research and application.