The main difference between PEEK (Polyether Ether Ketone) carbon fiber composite and unfilled PEEK lies in their composition and properties:

Composition:

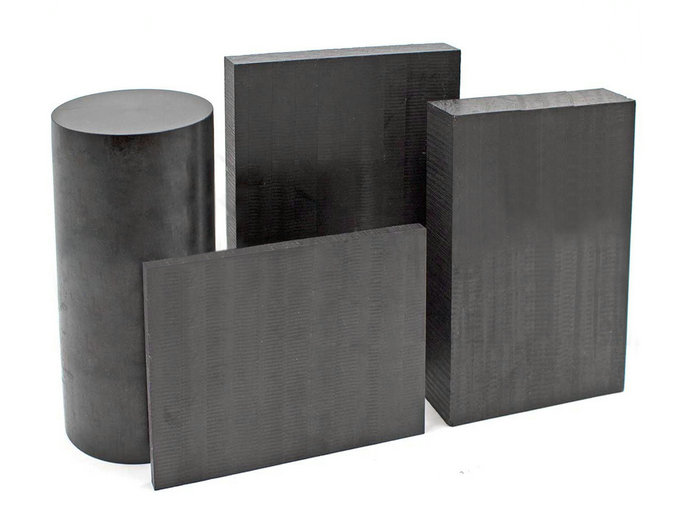

PEEK Carbon Fiber Composite: This material is a combination of PEEK resin and carbon fiber reinforcement. Carbon fibers are embedded within the PEEK matrix, enhancing its mechanical properties.

Unfilled PEEK: Unfilled PEEK is the pure PEEK resin without any additional reinforcement or additives.

Mechanical Properties:

PEEK Carbon Fiber Composite: The addition of carbon fibers significantly improves the mechanical properties of PEEK. Carbon fibers are known for their high strength-to-weight ratio and stiffness. Therefore, PEEK carbon fiber composites exhibit enhanced tensile strength, modulus of elasticity, and resistance to bending and deformation.

Unfilled PEEK: While PEEK itself is a high-performance thermoplastic with good mechanical properties, it may not be as strong or stiff as the carbon fiber composite version. Unfilled PEEK is often used in applications where chemical resistance, high-temperature stability, and electrical insulation are primary considerations.

Applications:

PEEK Carbon Fiber Composite: This composite is commonly used in applications where both the exceptional properties of carbon fiber and the unique characteristics of PEEK are required. It's utilized in aerospace, automotive, sports equipment, and other industries that demand high strength, low weight, and durability.

Unfilled PEEK: Unfilled PEEK is employed in applications where excellent chemical resistance and high-temperature performance are crucial. It's often used in medical devices, semiconductors, pumps, valves, and other industrial components.

Cost:

PEEK Carbon Fiber Composite:

The addition of carbon fiber reinforcement generally makes the composite more expensive than unfilled PEEK.

Unfilled PEEK:

This material is generally more cost-effective compared to carbon fiber composites.

In summary, PEEK carbon fiber composites offer superior mechanical properties due to the incorporation of carbon fibers, making them suitable for demanding applications that require exceptional strength and stiffness. Unfilled PEEK, on the other hand, excels in chemical resistance and high-temperature stability, making it a valuable choice for applications where these properties are essential. The choice between the two materials depends on the specific requirements of the application and the desired balance of properties.