Due to its excellent wear resistance, mechanical strength, hardness, impact resistance, and ease of molding, PEEK polymer has become the standard high-performance polymer for many of the most demanding applications in the transportation sector worldwide.

The advantages of polyether ether ketone (PEEK) in the automotive industry include:

1, It has much higher heat resistance and strength compared to traditional plastics, with a maximum temperature resistance of 260°C.

2, PEEK, when reinforced with fibers, has a tensile strength of up to 224 MPa, comparable to aluminum alloys.

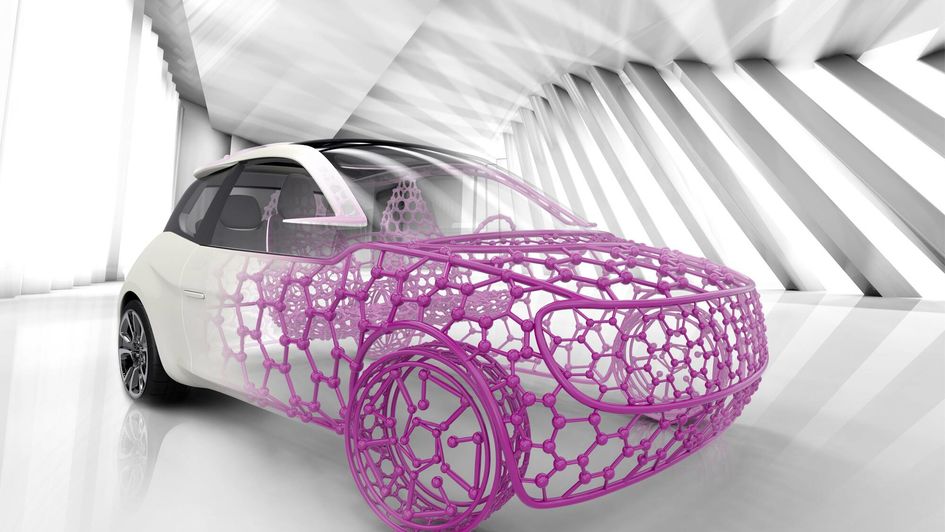

3, Meets requirements for automotive lightweighting, energy conservation, and new safety standards.

4, Exhibits excellent mechanical properties at high temperatures and maintains stability.

5, Demonstrates outstanding mechanical strength, impact resistance, and wear resistance, significantly improving the lifespan of parts.

6, Possesses excellent chemical resistance, with exceptional resistance to all automotive fluids, even at high temperatures, exhibiting excellent resistance to acids, alkalis, inorganic, and organic chemicals.

7, Offers excellent dimensional stability, low moisture absorption, and low coefficient of thermal expansion, meeting strict tolerance requirements for parts.

The successful substitution of steel, aluminum, copper, titanium, PTFE, and other high-performance materials in almost unrestricted application areas is evidence of PEEK polymers' superior performance and good processing characteristics.

Statistics show that there are nearly 50 components in automotive systems that can be made with PEEK resin, which can significantly improve vehicle performance and reduce manufacturing costs.

The detailed list of related components includes:

| Throttle Body Bushings | Timing Chain Tensioner | Oil Pump Rotors | Oil Pump Shafts | Distributer Gears | Transmission Thrust Washers |

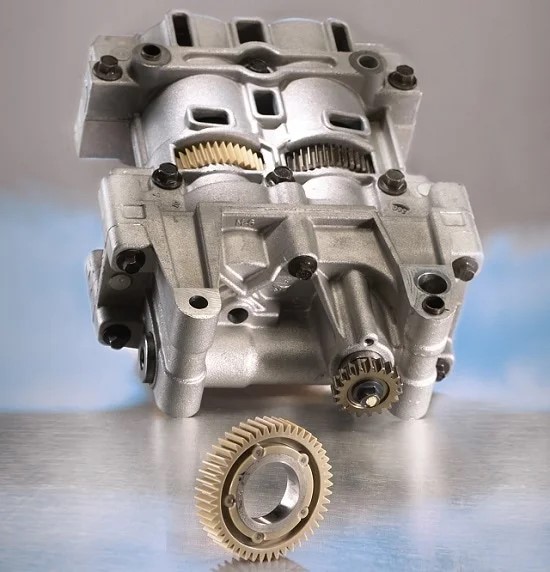

| Needle Bearings | Power Seat Components | Oil Pump Gears | Transmission Bushings | Power Window Gearing | Fuel Pump Gears |

| Water Pump Impeller | Transmission Valvers | Fuel Line Connector | Fuel Pump Motor Components | Engine Seals | Filter Housing Components |

| Brake Wear Sensors | Fuel Pump Bushongs | Turbo Changer Impellers | Transmission Seals | Tire Studs | Electric Window Motor Plugs |

| Turbo Changer Couplings | Ball Joint Liners | Bearing Cages | Electric Motor Thrust Washers | O2 Sensors | U-joint Bearings |

| Wheel Sensors | Sunroof Gears | O2 Wires | ABS Brake Seats | Brake Cylinder Components | HVAC Gearing |

| Transmission Wear Pads | Tie Rod Joint Liners | Shoch Absorber Components | Isolator Bolts | Power Steering Gears | Steering Shaft Isolators |

| Protective Sleeving and Braiding | EGR Temperature Sensor | ...... |

Victrex Application Cases:

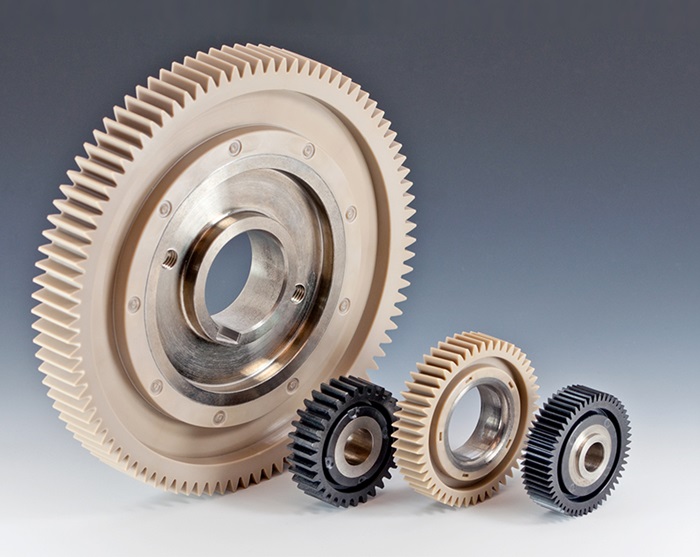

Victrex's product forms and components for the automotive industry include friction-optimized VICTREX™ PEEK polymer, APTIV™ films, and robust VICTREX HPG™ high-precision gears. These products collectively help improve carbon emission efficiency and durability, and contribute to reducing the overall cost of conventional, hybrid, and electric powertrain systems.

Victrex supports the development and testing of high-precision VICTREX HPG™ gears, as well as manufacturing these gear components for integration into larger systems. As a recent achievement, Victrex's gear design and manufacturing facility in Gallowsburg, USA, has obtained IATF 16949 certification, recognizing its ability to meet the needs of tier one suppliers/original equipment manufacturers.

In electric propulsion, PEEK film electrical insulation helps improve thermal management, achieve reliable operation, and reduce overall system costs. As the automotive industry transitions to electric vehicles, there is a need for more efficient high-density electric motors at lower costs. In the most widely used permanent magnet synchronous motors (PMSM), the design of the insulation system plays a crucial role.

A widely recognized third-party expert conducted computer simulations on an 80 kW electric motor installed, indicating that in electric motors of the same size, torque output increased by 5% by reducing the thickness of APTIV™ slot liners by 40%, and copper content increased by 2% (slot fill factor). Other simulations show that compared to traditional composite films, APTIV™ films exhibit excellent thermal conductivity, improving thermal management and reducing peak winding temperatures by 2-3°C.

So far, the PEEK industry has developed grades with different properties such as high wear resistance, high strength, high temperature resistance, low friction coefficient, impact resistance, fatigue resistance, and high flowability to meet the application requirements of six major systems in traditional fuel-powered vehicles: engines, transmissions, suspension/steering, brakes, fuel, and HAVC. Currently, more than 50 PEEK components have been commercialized.

In recent years, with the rise of new energy vehicles, the comprehensive performance advantages of PEEK have been recognized by the new energy vehicle industry, and more and more successful applications of PEEK have been developed in the development of lithium-ion battery and hydrogen fuel cell vehicles.