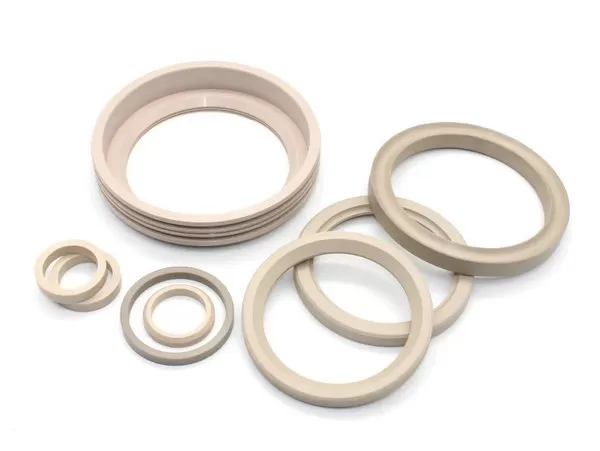

Our PEEK backup rings provide reliable anti-extrusion support for O-ring seals in high-pressure, high-temperature environments. Made from chemically resistant, low-friction PEEK material, they prevent seal extrusion and extend seal life in demanding industrial applications.

_______________________________________________________________________________________________________________________________________________________________________

PEEK backup rings, also known as anti-extrusion rings, are critical components designed to support elastomeric O-ring seals by preventing extrusion under high pressure and temperature conditions. Manufactured from high-performance polyetheretherketone (PEEK), these backup rings withstand continuous temperatures up to 260°C (500°F) and pressures up to 20,000 psi, making them ideal for demanding sealing applications in hydraulic valves, chemical pumps, injection molding machines, and subsea equipment.

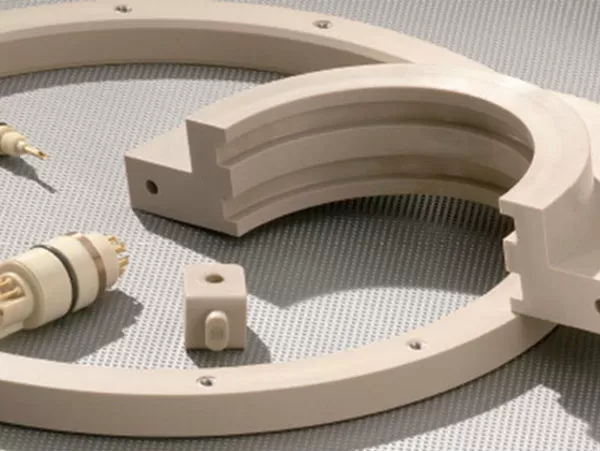

The unique combination of PEEK’s high modulus, excellent chemical resistance, and low friction properties ensures that backup rings maintain seal integrity by blocking extrusion gaps and reducing wear on O-rings. PEEK backup rings are available in virgin and filled grades, with fillers enhancing strength and hardness for extreme conditions. Their low-stress design, including scarf-cut split rings, accommodates thermal expansion without damaging seals, thereby preventing leakage and premature failure.

Key Benefits

High-Temperature & Pressure Resistance: Operates reliably up to 260°C and 20,000 psi.

Chemical Compatibility: Resistant to fuels, lubricants, acids, bases, and various harsh chemicals.

Low Friction & Self-Lubrication: Minimizes wear and extends seal life.

Custom & Standard Sizes: Available in machined, molded, and near-net shapes up to 24” diameter.

NORSOK M-710 Compliant: Suitable for sour gas and harsh energy market environments.

Widely used in oil & gas, aerospace, pharmaceutical, agricultural machinery, and industrial fluid systems, PEEK backup rings enhance sealing reliability and reduce maintenance costs. Their ability to perform in extreme conditions without metal-to-metal contact prevents hardware damage and ensures long-term operational safety.

Choose PEEK backup rings for superior extrusion resistance, chemical durability, and thermal stability to protect your sealing systems in the most challenging environments.